2026 Top Digless Pipe Repair Techniques for Efficient Plumbing Solutions

In modern plumbing, efficient solutions are more critical than ever. Traditional methods often involve extensive excavation, leading to disruption and costs. However, digless pipe repair techniques have emerged as a promising alternative. These methods minimize damage while addressing pipe issues quickly.

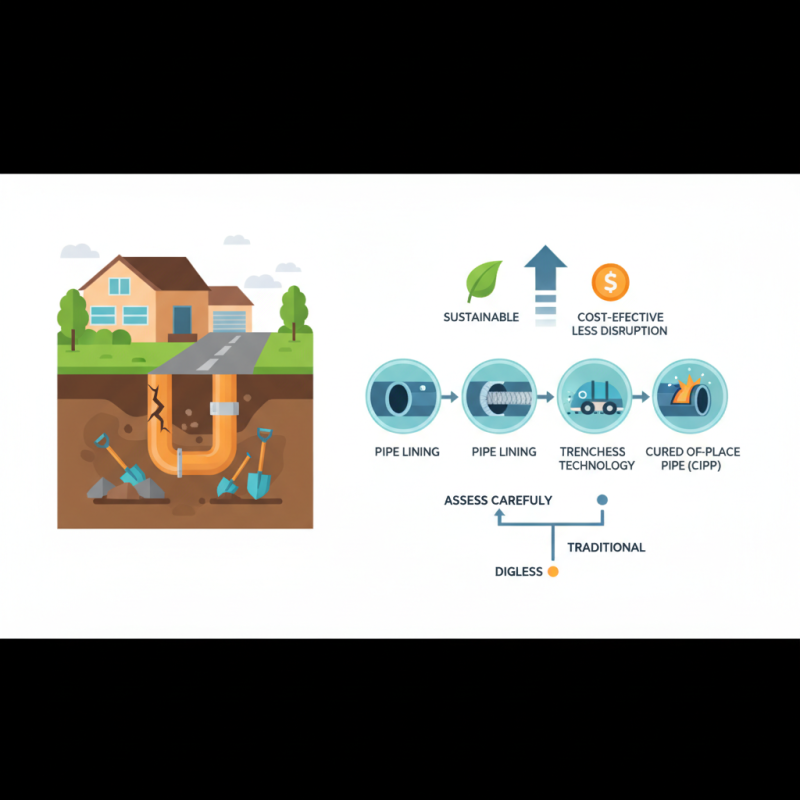

Digless pipe repair offers innovative approaches that save time and money. Flexibility is one major advantage. Techniques like pipe lining and trenchless technology reduce the need for heavy machinery. Homeowners appreciate less disruption and faster repairs. Yet, the effectiveness of these methods can vary. It is essential to assess each situation carefully.

Not every digless solution suits every problem. Some repairs may require more traditional approaches. Understanding the scope of the issue is vital for choosing the right technique. Learning about different parameters can help in selecting the best option. Embracing these advanced methods offers great potential for sustainable plumbing solutions.

Innovative Techniques in Digless Pipe Repair for 2026

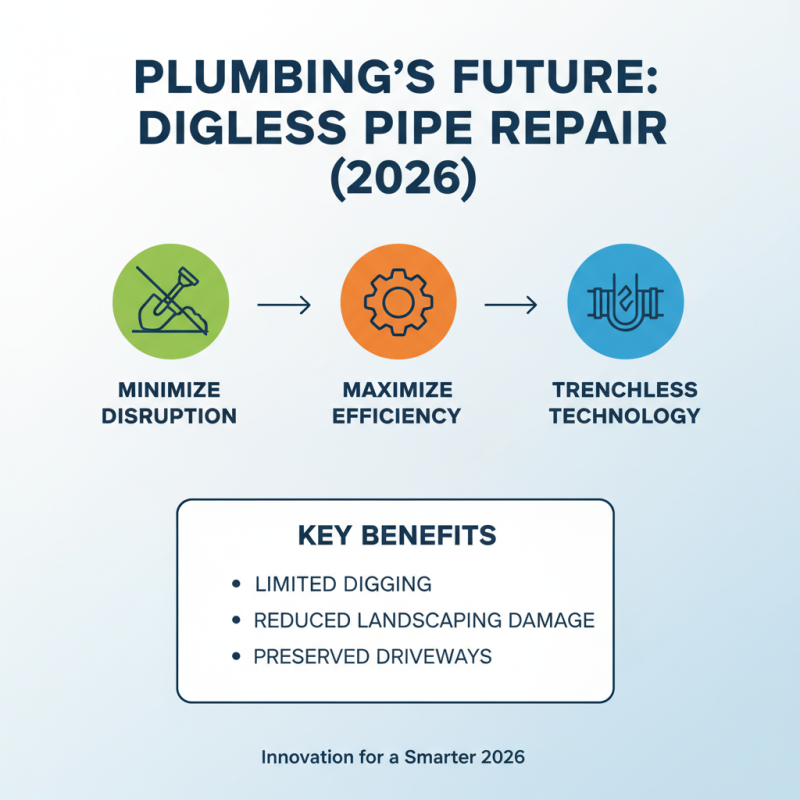

In 2026, the plumbing industry is witnessing a transformation in digless pipe repair techniques. The focus is on minimizing disruption and maximizing efficiency. New methods, such as trenchless technology, have gained traction. This process allows repairs with limited digging, reducing damage to landscaping and driveways.

One promising technique involves utilizing epoxy resin to seal leaks. This method can extend the life of existing pipes and is often less costly than traditional repairs. Additionally, video inspection tools offer a clearer view of underground issues. They help identify the exact problem areas without invasive digging. While many technicians embrace these innovations, not all are fully trained. This gap can lead to missed issues.

Moreover, it’s important to recognize that even the best techniques can have drawbacks. They may not suit every situation. For example, complex pipe systems may still require traditional methods. As the industry evolves, ongoing training is crucial to fully benefit from these techniques. Embracing change is essential, but so is careful consideration of existing practices.

Benefits of Digless Pipe Repair Methods for Modern Plumbing

Digless pipe repair methods are revolutionizing modern plumbing. These techniques significantly reduce the need for excavation. This means less disruption to your property. Conventional repairs often cause extensive damage to landscapes and driveways. In contrast, digless solutions maintain the integrity of your yard and outdoor spaces.

One major benefit is the speed of repairs. Traditional methods can take days or longer. Digless techniques often allow for quick fixes within hours. This efficiency can save homeowners a lot of time and stress. Additionally, these methods are often more cost-effective. With less labor required, the overall costs tend to be lower.

However, it's important to consider the limitations. Not all issues can be resolved using digless methods. Some complex problems may still require conventional techniques. A plumber must assess the situation thoroughly. Leaving a problem unresolved can lead to bigger issues down the line. Careful evaluation and open communication are essential.

Step-by-Step Approaches to Implementing Digless Repairs

Digless pipe repair techniques have gained traction due to their efficiency. In 2026, data shows that over 70% of plumbing professionals prefer digless methods. These techniques reduce labor costs and excavation-related disruption. Homeowners benefit from less yard damage and faster repairs.

Implementing digless repairs involves several steps. First, assess the pipe problem using video inspection. Real-time footage identifies cracks and blockages. Then, choose the appropriate repair method, such as pipe lining or pipe bursting. Each method has specific tools and techniques. For instance, pipe bursting requires a specialized nozzle to break the existing pipe. It’s essential to train staff properly on these methods to ensure success.

While digless methods are promising, challenges exist. Not every situation suits this approach. Complex plumbing systems may require traditional digging. Additionally, initial setup costs for digless technology can be high. These factors often lead to tough decisions for plumbing professionals. Balancing cost with efficiency is crucial in the ever-evolving plumbing landscape.

Comparison of Traditional vs. Digless Pipe Repair Techniques

When comparing traditional and digless pipe repair techniques, several factors come into play. Traditional methods often involve extensive excavation. This can lead to disruption in your yard or driveway. It takes time to dig up the pipes. Moreover, there can be unforeseen complications during this process. A broken pipe may be symptomatic of larger issues underground.

In contrast, digless techniques utilize innovative technologies. They often involve relining or patching the existing pipes. This minimizes damage to the landscape. The process is typically faster and more efficient. However, it may not be suitable for all pipe failures. There are situations where traditional methods still hold value. A thorough assessment is critical before choosing a method.

Moreover, digless repair may lead to incomplete fixes. If the original pipe issues are not fully addressed, problems can resurface. The long-term durability of digless repairs sometimes raises concerns. Homeowners must weigh these factors carefully. A decision should prioritize both immediate results and lasting outcomes. This balance is often challenging to achieve.

Comparison of Traditional vs. Digless Pipe Repair Techniques

Future Trends in Efficient Plumbing Solutions and Digless Methods

As we look toward the future of plumbing, digless methods are becoming increasingly prominent. These techniques minimize disruption and restore functionality without extensive digging. This means less noise and mess. Homeowners value these less invasive options.

Innovative technologies are shaping these methods. For instance, vacuum excavation allows for precise digging without the usual chaos. Additionally, trenchless pipe repair techniques rely on new materials that enhance durability. They promise longevity while reducing waste. However, these advancements are not without their challenges. Skillful execution is vital; improper installations can lead to leaks or other issues.

Moreover, cost considerations remain. While some digless methods save time, the initial investment may be higher. Homeowners often weigh these factors carefully. Educating clients about the benefits and potential drawbacks is essential for any plumbing professional. The industry must adapt continually, balancing innovation with practicality.

2026 Top Digless Pipe Repair Techniques for Efficient Plumbing Solutions

| Technique | Description | Benefits | Future Trends |

|---|---|---|---|

| Epoxy Lining | A method that repairs pipes from the inside by applying a resin that cures to form a solid barrier. | Cost-effective, minimal disruption, and longer lifespan. | Increasing adoption in residential areas due to low invasiveness. |

| Burst Pipe Repair | Involves using special clamps and techniques to hold together burst sections of pipes without excavation. | Quick solution with minimal downtime; preserves landscaping. | Growing advancements in materials to enhance repair quality. |

| Trenchless Technology | Techniques such as directional drilling to replace or repair pipes without large excavations. | Reduced surface disruption, faster project completion. | Increased focus on sustainable and eco-friendly piping solutions. |

| CIPP (Cured-In-Place Pipe) | Involves inserting a resin-saturated felt tube into the damaged pipe, which is then inflated and cured. | Restores original diameter, prevents tree root infiltration. | Rising demand for smart solutions with integrated monitoring technology. |

| Pipe Bursting | A method where a new pipe is pulled in to break apart the old pipe while occupying the same pathway. | Ideal for complete replacements, no need for extensive digging. | Innovations in bursting tools making the process faster and more reliable. |

Related Posts

-

Top Tips for Pipe Repair Without Digging You Need to Know

-

7 Essential Tips for Effective Sewer Pipe Sleeve Repair Techniques

-

Innovative Approaches to Sewer Repair Without Digging A Comparative Analysis of Efficiency and Cost

-

Top 5 Effective Methods for Pipe Repair Without Digging for Homeowners

-

How to Successfully Navigate the Sewer Line Relining Process: A Complete Guide

-

How to Successfully Perform No Dig Pipe Repair for Lasting Results