Top 10 Benefits of Internal Pipe Repair Sleeves Explained?

In the world of plumbing, maintaining pipes is crucial. An internal pipe repair sleeve offers a viable solution for damaged pipes. These sleeves effectively address issues like leaks and corrosion without major disruptions.

Many homeowners and businesses face the dilemma of how to fix a pipe without extensive excavation. Internal pipe repair sleeves provide a unique option. They are lightweight yet durable. Installation is often quick and minimizes downtime.

However, it’s essential to consider the long-term effects. Will the sleeve truly extend the life of the pipe? Is the investment worth it? While they can be effective, the need for regular inspections remains. Addressing each plumbing concern with care is vital for optimal results.

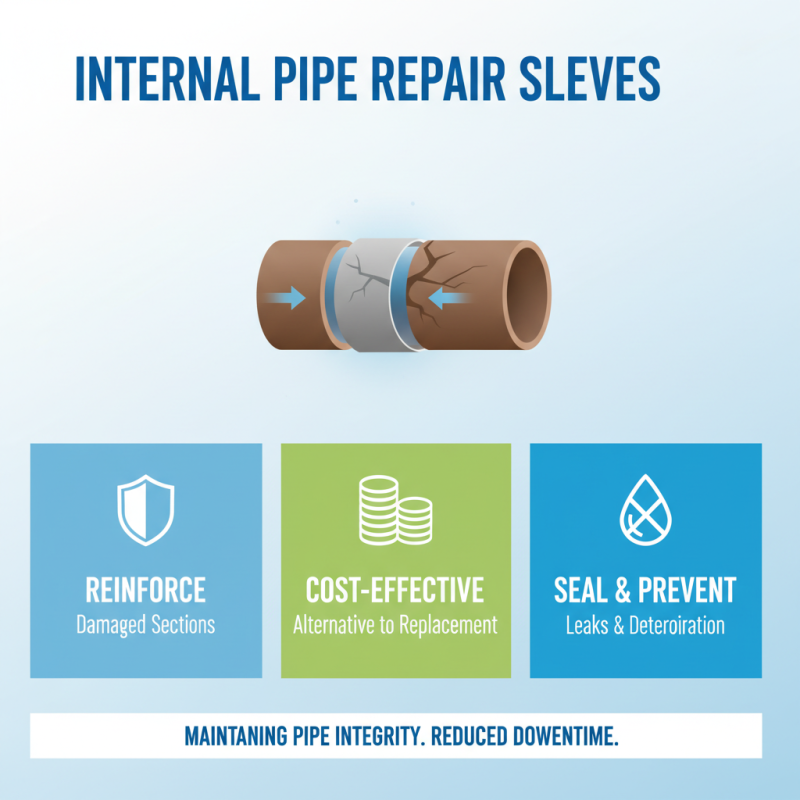

Overview of Internal Pipe Repair Sleeves and Their Functionality

Internal pipe repair sleeves have emerged as a crucial solution for maintaining pipe integrity. These innovative sleeves function by reinforcing damaged sections, providing a cost-effective alternative to full pipe replacement. They can seal leaks and prevent further deterioration, a significant advantage in industries where downtime is costly.

According to a report from the National Institute of Standards and Technology, about 25% of water is lost annually due to pipe leaks. Internal pipe repair sleeves can reduce this wastage effectively. They are designed to accommodate various pipe materials and sizes, ensuring usability across multiple contexts. The installation process is straightforward, allowing for quick repairs without extensive excavation.

Tips for using internal pipe repair sleeves include ensuring the pipe is clean and dry before application. This prevents issues with adhesion. Regular inspections can also highlight potential weaknesses before they escalate. Keep in mind that while sleeves are durable, they are not a permanent fix. Regular maintenance is key to avoiding recurring issues.

Cost-Effectiveness of Using Repair Sleeves Over Traditional Methods

Repair sleeves offer a cost-effective solution for internal pipe issues. Traditional methods often require extensive excavation and replacement. This can lead to high labor costs and lengthy downtime. Repair sleeves, however, can be installed quickly with minimal disruption. They effectively seal leaks and reinforce pipe integrity without major construction work.

Using repair sleeves, you save on materials. The need for additional fittings and labor is significantly reduced. This method is particularly beneficial in tight spaces where access is limited. Yet, it raises questions about long-term durability compared to traditional repairs. Some technicians still prefer conventional methods, citing concerns about the longevity of sleeves under extreme conditions.

Visualizing this, consider a typical repair job. The excavation process eats up time and budget. A repair sleeve could cut these expenses drastically. However, would it truly withstand the test of time in harsher environments? This uncertainty is something to consider. Repair sleeves may seem appealing, but each method has its pros and cons depending on specific situations.

Enhanced Durability and Longevity of Pipelines with Repair Sleeves

Repair sleeves significantly enhance the durability of pipelines. They provide a robust solution for leaks and structural weaknesses. By reinforcing the affected areas, these sleeves extend the lifespan of the piping system. They are designed to withstand high-pressure conditions and temperature fluctuations. This protection reduces the risk of failure or costly repairs down the road.

The installation process is generally straightforward, allowing for quick repairs. However, some challenges may arise during installation, such as surface preparation. Proper cleaning and alignment are crucial for effective bonding. Without attention to detail, the desired longevity may not be achieved. Regular inspections ensure that the repair sleeve maintains its integrity over time.

Incorporating repair sleeves can lead to significant cost savings. They minimize the need for extensive excavation and replacement of entire pipeline sections. Yet, reliance on sleeves alone might not always suffice. Comprehensive monitoring and maintenance remain essential to ensure long-term functionality. Awareness of potential limitations is key to maximizing benefits.

Minimal Disruption: Advantages of In-Situ Pipe Repair Solutions

In-situ pipe repair solutions offer significant advantages, particularly regarding minimal disruption to daily operations. Traditional repair methods often require extensive excavation and lengthy downtime. However, in-situ methods can be completed in a fraction of the time, typically within hours rather than days. A report by the American Society of Civil Engineers indicates that minimizing disruption can lead to cost savings upwards of 30%, offering both time and economic efficiency.

These systems often utilize advanced materials that bond to the existing pipe. This bond reinforces the structure without the need for invasive processes. For instance, according to the World Bank, utilizing less invasive methods can reduce environmental impact by up to 25%. In densely populated urban areas, the ability to repair pipes without extensive digging preserves the landscape and maintains community flow.

Nevertheless, challenges remain. The success of in-situ repairs depends on the condition of the existing pipe. Not all pipes can benefit from this approach. It requires a thorough assessment to determine viability. In some cases, materials may break down further, making future repairs necessary. This calls for ongoing monitoring and maintenance strategies. Balancing efficiency with longevity continues to be a complex issue in the industry.

Top 10 Benefits of Internal Pipe Repair Sleeves

| Benefit | Description | Estimated Time Savings | Cost Efficiency |

|---|---|---|---|

| Minimal Disruption | Repair can be conducted without excavation, reducing disturbance. | Up to 50% faster | Saves up to 30% on labor costs |

| Strength Restoration | Reinforces existing pipes and restores structural integrity. | Immediate restoration | Reduces the need for complete pipe replacement |

| Versatility | Applicable to various pipe materials and sizes. | Variable depending on application | Cost-effective across multiple scenarios |

| Long-lasting Solution | Durable materials provide a lasting fix, extending pipe life. | Years of protection | Minimizes future repair costs |

| Environmental Benefits | Less waste generated compared to traditional methods. | Reduced carbon footprint | Contributes to sustainability goals |

| Quick Deployment | Fast installation requires less downtime. | Typically a few hours | Reduces overall project duration |

| Reduced Risk | Minimizes the chance of pipe failure during repairs. | Lower maintenance risks | Decreases insurance costs |

| Expertise Utilization | Utilizing specialized techniques and knowledge. | Skill-efficient procedures | Optimized labor use |

| Increased Property Value | Improved infrastructure enhances overall property value. | Market perception benefits | Higher resale potential |

| Compliance and Safety | Meets regulatory standards while ensuring public safety. | Ongoing adherence to safety protocols | Avoids fines or penalties |

Environmentally Friendly Aspects of Internal Pipe Repair Technologies

Internal pipe repair technologies have evolved significantly, emphasizing eco-friendly solutions. For example, internal pipe repair sleeves provide a sustainable alternative to traditional excavation methods. These sleeves are often made from recyclable materials, reducing environmental impact. According to a 2022 industry report, using such technologies can decrease construction waste by up to 70%. This reduction is crucial for promoting a greener future.

Moreover, internal pipe repair methods consume less energy compared to traditional repairs. They require minimal heavy machinery and often rely on manual labor instead. The same report indicated that energy consumption could be cut by 50% in repair processes. This lower energy demand contributes to a decrease in carbon emissions. Yet, some industry professionals express concerns about the longevity of these materials, prompting discussions on potential improvement areas.

Another aspect is water conservation. Traditional pipe repair methods often involve significant water usage for testing and cleaning. Internal sleeves limit this usage by creating a seal that minimizes leaks. However, questions remain about the long-term effectiveness of these repairs. While they present an immediate solution, ongoing assessments are necessary to ensure they hold up over time. This continuous reflection is vital for maintaining environmental standards in the industry.

Related Posts

-

Top Tips for Effective Sewer Repair Solutions?

-

What is CIPP Sewer Repair? Benefits, Process, and Costs Explained

-

Top Tips for Pipe Repair Without Digging You Need to Know

-

How to Effectively Address Sewer Issues with No-Dig Solutions

-

Revolutionizing Pipe in Pipe Repair Techniques with Advanced Leak Detection Data

-

How to Identify Common Symptoms of Pump Issues Before Calling for Repair