How to Successfully Navigate the Sewer Line Relining Process: A Complete Guide

When faced with aging or damaged sewer lines, homeowners often seek effective solutions to restore proper function without the need for extensive excavation. Sewer line relining emerges as a cutting-edge repair method that not only minimizes disruption but also enhances the longevity of the plumbing system. This process involves the installation of a new liner within the existing sewer pipe, creating a durable barrier that can withstand the harsh conditions of sewage flow. As a result, understanding the nuances of sewer line relining becomes essential for anyone considering this innovative repair technique.

In this comprehensive guide, we will delve into the various stages of the sewer line relining process, offering insights into preparation, execution, and post-repair maintenance. Whether you are a homeowner contemplating this option or a property manager overseeing utility repairs, grasping the essentials of sewer line relining is crucial. By navigating this process successfully, you can ensure that your sewer lines operate efficiently for years to come, ultimately saving time, money, and reducing the environmental impact of traditional repair methods. Join us as we explore the steps necessary to optimize your sewer line relining journey.

Overview of Sewer Line Relining Process

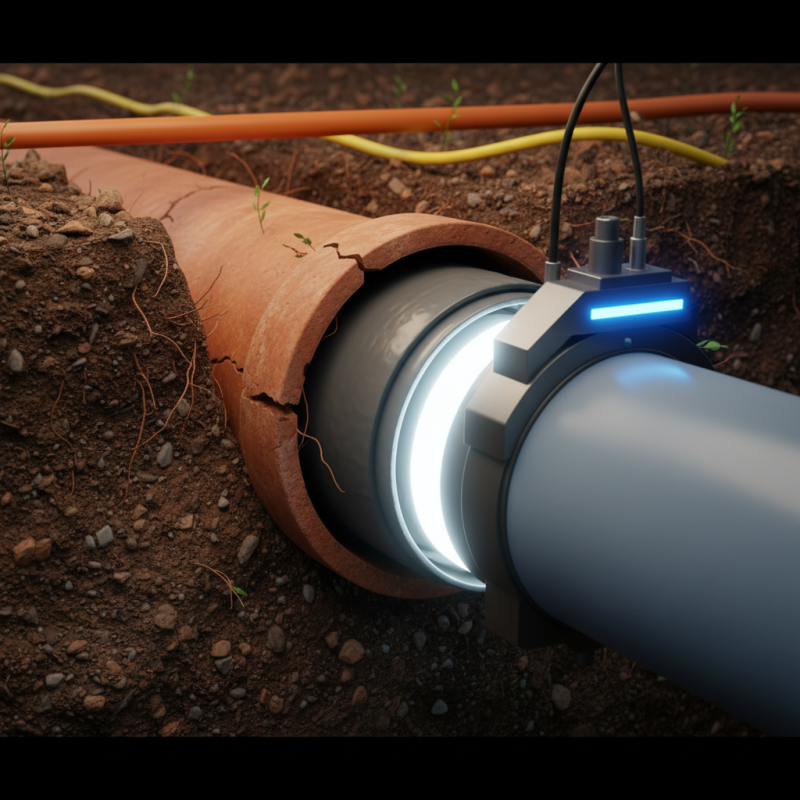

Sewer line relining is a crucial maintenance process that serves to rehabilitate damaged pipes without the need for extensive excavation. The process involves inserting a resin-coated liner into the existing sewer line, which then adheres to the interior of the damaged pipe. Once the liner is in position, it is inflated and cured, creating a new, seamless pipe within the old one. This method not only minimizes disruption to properties and landscapes but also significantly extends the lifespan of the sewer system.

Understanding the steps involved in the sewer line relining process is vital for ensuring its success. Initially, a thorough inspection using video camera technology is performed to assess the condition of the pipes and identify any blockages or damage. After a comprehensive evaluation, the appropriate size and type of liner are selected. Following the preparation of the site, the liner is installed and treated, typically using heat or ultraviolet light to cure it. The final step involves re-examining the system to confirm that the relining has effectively restored the functionality of the sewer line. Proper navigation of this process can lead to reduced maintenance costs and improved reliability of the sewer infrastructure.

Understanding the Benefits of Sewer Line Relining

Sewer line relining is a cutting-edge technique that offers numerous benefits, transforming the landscape of underground pipe repairs. One of the most compelling advantages is its cost-effectiveness; studies have shown that relining can reduce the overall repair costs by as much as 50% compared to traditional excavation methods. This is particularly relevant in urban environments where digging up streets can incur additional expenses, from road closures to traffic management.

In addition to saving money, sewer line relining minimizes disruption. With a typical relining project taking only a fraction of the time compared to conventional repairs, homeowners and businesses experience less downtime and inconvenience. Reports indicate that most relining jobs can be completed within a few hours, and after the curing process, the pipes are ready for immediate use. This efficiency is a significant selling point for property managers and homeowners alike.

Tips for Successful Sewer Line Relining:

- Before starting the relining process, it’s crucial to have a thorough inspection of the existing pipes. Utilizing video camera inspections can help identify issues and provide insight into the most effective relining strategy.

- Ensure that the materials used for relining are of high quality, as this impacts the longevity and effectiveness of the repair. Current industry data suggest that properly installed relined pipes can last upwards of 50 years, offering excellent long-term value.

- Engage with certified professionals who specialize in sewer line relining. Their expertise ensures that the process adheres to industry standards and minimizes the risk of future complications.

Step-by-Step Guide to Preparing for Relining

When preparing for the sewer line relining process, it’s essential to begin with a thorough evaluation of the existing pipes. This involves conducting a detailed inspection using video technology to identify blockages, leaks, or structural issues within the sewer line. Understanding the current condition of your pipes is crucial, as it will inform the next steps and help determine the most effective relining method. Make sure to clear any debris or obstructions, ensuring that the area around the sewer line is accessible for the relining crew.

Once the inspection is complete, gather all necessary materials and tools for the relining process. This includes selecting appropriate lining materials that are compatible with your existing pipes and ensuring that all safety equipment is on hand for the technicians involved. It’s also important to notify local utility companies and possibly neighbors, as the relining work might cause temporary disruptions. By preparing comprehensively, you create a smoother workflow, potentially reducing the time and costs associated with the project while ensuring a long-lasting solution for your sewer line issues.

This chart illustrates the estimated time spent in hours on each step of the sewer line relining process. It provides a visual representation to aid in understanding where most time is allocated during the relining project.

Common Techniques Used in Sewer Line Relining

Sewer line relining is a practical solution for rehabilitating damaged pipes without the need for extensive excavation. Several common techniques are employed in this process, each with its own benefits. The most widely used method is the Cured-in-Place Pipe (CIPP) technique, where a resin-saturated liner is inserted into the existing pipe and then cured, forming a strong, seamless new pipe within the old one. This method is cost-effective and minimizes disruption to the surrounding area.

Another technique is pipe bursting, which entails breaking apart the damaged pipe while simultaneously installing a new one in its place. This approach is particularly effective for severely damaged lines and can increase the overall capacity of the sewer system. Additionally, lateral reinstatement allows for the restoration of service connections to the newly lined pipes, ensuring that the system functions efficiently post-repair.

Tips: Always consult with a professional to assess the most suitable relining method for your specific situation. Regular maintenance of your sewer lines can prevent significant issues in the future. Additionally, being aware of common signs of sewer line problems, such as unusual odors or slow drainage, can help address issues before they require extensive repairs.

Post-Relining Maintenance and Considerations

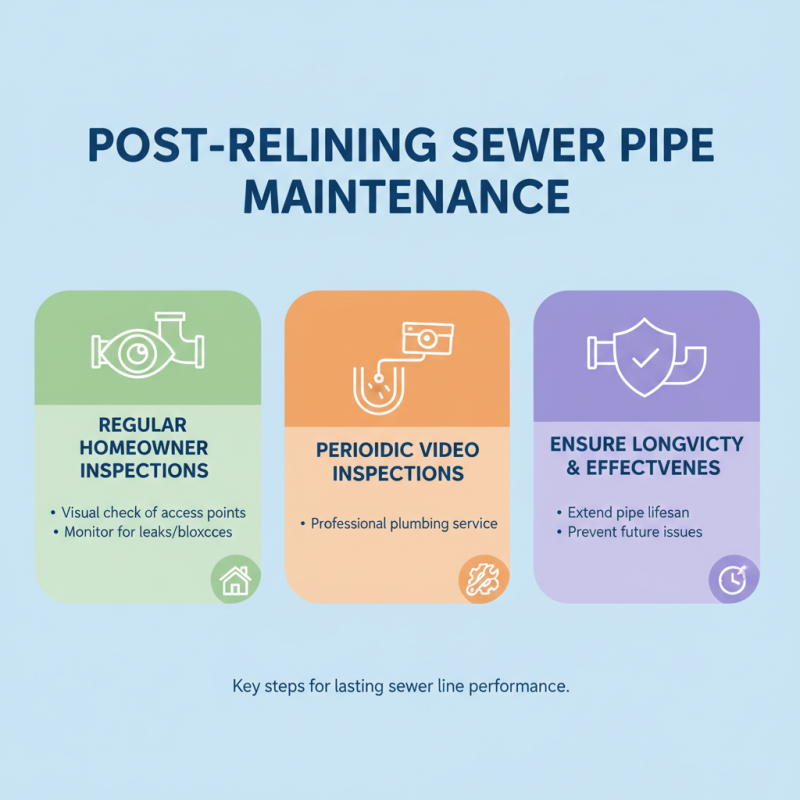

Post-relining maintenance is crucial to ensure the longevity and effectiveness of the newly lined sewer pipes. After the relining process, homeowners should conduct regular inspections to monitor the condition of their sewer lines. This includes visually assessing access points and monitoring for any signs of leaks or blockages. Using a professional plumbing service to perform periodic video inspections can offer an in-depth view of the interior condition of the pipelines.

Additionally, it’s important to adopt proper waste disposal practices to maintain the integrity of the newly lined sewer system. Homeowners should refrain from flushing non-biodegradable items or pouring grease down the drains, as these can lead to future clogs and damage. Regular maintenance schedules, including preventive cleaning and minor repairs, can help preserve the lifespan of the sewer line and ensure optimal water flow throughout the system. Investing in routine checks and following best practices for waste management will ultimately contribute to a more efficient and durable sewer line setup.

Related Posts

-

Innovative Approaches to Sewer Repair Without Digging A Comparative Analysis of Efficiency and Cost

-

Unlocking the Advantages of No Dig Sewer Repair for Modern Infrastructure

-

How to Use Trenchless Technology for Effective Sewer Repair Solutions

-

How to Effectively Address Sewer Issues with No-Dig Solutions

-

Creative Options for Sewer Repair Without Digging Methods You Should Consider

-

Revolutionizing Home Maintenance: The Scientific Benefits of Digless Pipe Repair Techniques