What is Pump Repair and How Can It Benefit Your Equipment?

Pump repair is a critical service that can significantly enhance the efficiency and longevity of your equipment. According to a report by the Hydraulic Institute, nearly 40% of all pumps experience premature failure due to inadequate maintenance. This alarming statistic highlights the importance of timely and effective pump repair practices.

Industry expert, Dr. Jane Smith, emphasizes this need by stating, "Regular pump repair is essential to avoid unexpected breakdowns." The implications of neglecting pump repair can lead to costly downtimes and inefficient operations. However, many companies still overlook this essential maintenance aspect, leading to suboptimal performance.

Neglecting pump repair not only hampers productivity but can also strain resources. From rising energy costs to increased labor expenses, the risks are tangible. By investing in proper pump repair, businesses can significantly reduce these overhead costs and optimize their operations. This is a critical consideration for anyone managing industrial equipment today.

Understanding Pump Repair: Definition and Importance

Pump repair is essential for maintaining efficient equipment. A pump is a crucial part of many systems. It helps to move fluids, and any failure can disrupt operations. Understanding what pump repair entails is vital. It involves diagnosing issues and implementing fixes.

Issues can vary from mechanical failures to leaks. Regular inspection is important. It allows for early detection of problems. Neglecting repairs can lead to costly downtime. Each pump repair is unique and may require a tailored approach. Sometimes, minor issues can escalate if overlooked.

The importance of pump repair cannot be overstated. Proper functioning enhances safety and performance. It extends the life of your equipment. Ensuring that pumps work properly is not just beneficial; it is necessary. Equipment reliability depends on effective repair and maintenance strategies. Neglect may lead to failures that impact productivity.

Common Types of Pumps and Their Repair Needs

Pumps are essential in various industries. Each pump type has unique needs for repair and maintenance. Centrifugal pumps often face issues like cavitation and seal leaks. These problems can cause inefficiencies. Regular inspection is crucial to spot these challenges early.

Diaphragm pumps also have specific repair requirements. They may experience diaphragm failures or valve issues. These can lead to fluid leaks and reduced performance. Swift repairs can restore their function and prevent further damage. Users need to be aware that neglecting these signs can result in more significant failures.

Positive displacement pumps are no exception. They might suffer from wear and tear over time. Components like gears or pistons can degrade. Monitoring for unusual noises or vibrations is essential. Failing to address these concerns quickly can cause serious operational disruptions. Regular maintenance and timely repairs can enhance the efficiency and lifespan of these pumps.

What is Pump Repair and How Can It Benefit Your Equipment? - Common Types of Pumps and Their Repair Needs

| Pump Type | Common Issues | Repair Needs | Benefits of Repair |

|---|---|---|---|

| Centrifugal Pump | Cavitation, seal leaks | Replace seals, impeller inspection | Increased efficiency, reduced downtime |

| Positive Displacement Pump | Wear and tear, valve malfunctions | Check valves, replace rotors | Consistent flow, improved performance |

| Diaphragm Pump | Diaphragm rupture, air leaks | Replace diaphragm, tighten fittings | Enhanced reliability, reduced maintenance costs |

| Gear Pump | Oil leakage, gear wear | Replace gears, inspect housing | Increased lifespan, improved screw output |

| Peristaltic Pump | Tube degradation, pressure loss | Replace tubing, check rollers | Lower risk of contamination, precise dosing |

The Pump Repair Process: Step-by-Step Breakdown

The pump repair process is crucial for manufacturing and industrial sectors. Understanding this process can enhance equipment longevity. Each repair involves several steps.

First, technicians diagnose the issue. Accurate diagnosis is vital. A misdiagnosis can lead to further problems. According to industry data, up to 30% of pump failures stem from improper maintenance.

After diagnosis, technicians disassemble the pump. This step reveals hidden issues. Damaged components are identified at this stage. They must be replaced carefully. Approximately 25% of repair costs arise from parts that are not installed correctly.

Attention to detail is key. The final step involves reassembly and testing. This ensures the pump operates efficiently. Reports indicate that a well-repaired pump can improve efficiency by 10-15%. However, many overlook the importance of regular maintenance assessments. Ignoring minor issues can lead to costly repairs later.

Benefits of Regular Pump Maintenance and Repair

Regular pump maintenance is essential for optimal performance. Over time, wear and tear can reduce efficiency. This leads to unexpected downtime and costly repairs. Keeping pumps in good condition helps prevent such issues. By regularly checking components, you ensure everything runs smoothly.

Here are some tips:

1. Inspect seals and gaskets frequently. These parts often wear out first.

2. Regularly check for leaks. A small leak can quickly grow larger.

3. Change fluids according to the manufacturer’s guidelines. Dirty fluids can damage internal parts.

Handling pump repairs promptly benefits equipment longevity. Neglecting minor issues can escalate into major problems. It's easy to overlook small noises or vibrations. Yet, these could indicate something is wrong. Pay attention to these signs. Addressing them early can save time and money. Regular care keeps everything in shape. Remember, an ounce of prevention is worth a pound of cure.

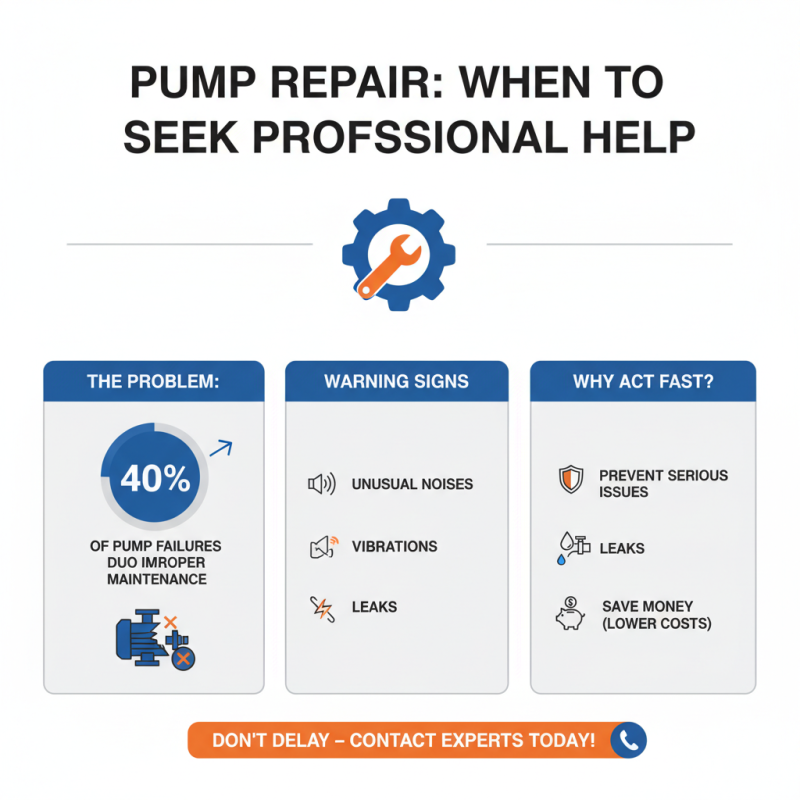

When to Seek Professional Help for Pump Repair

Pump repair is crucial for maintaining operational efficiency in various industries. Identifying the right moment to seek professional assistance is key. According to industry studies, around 40% of pump failures are due to improper maintenance. If you notice unusual noises, vibrations, or leaks, it’s time to act. Delaying repairs can lead to more severe issues and higher costs.

Additionally, regular inspection can extend your equipment’s life. Reports indicate that timely maintenance can improve pump efficiency by up to 25%. A professional can conduct a thorough analysis and pinpoint underlying problems. Using a systematic approach, they often find issues that might be overlooked. Trusting experts can save time and prevent accidents.

In many cases, equipment owners hesitate to get help. Some believe they can manage repairs themselves. This can lead to flawed fixes. Mistakes may exacerbate existing issues. Investing in quality repair services pays off. Always prioritize safety and functionality over convenience. Your equipment deserves expert care to ensure productivity and longevity.

Related Posts

-

Comprehensive Pump Repair Checklist for Efficient Plant Operations and Reduced Downtime

-

How to Identify Common Symptoms of Pump Issues Before Calling for Repair

-

2025 Top Tips for Effective Pump Repair: Common Issues and Solutions

-

Top 10 Effective Techniques for Well Pipe Repair You Should Know

-

Understanding Sewer Line Relining: A Comprehensive Guide to Modern Pipeline Repair Techniques

-

How to Successfully Perform No Dig Pipe Repair for Lasting Results