How to Successfully Perform No Dig Pipe Repair for Lasting Results

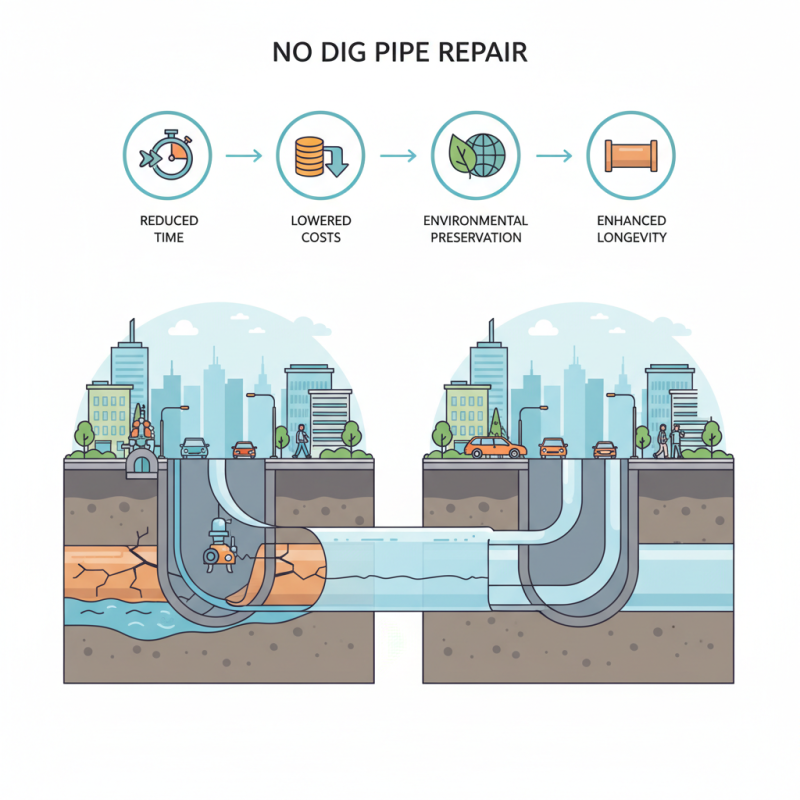

In recent years, the utility and effectiveness of no dig pipe repair methods have gained recognition across the plumbing and construction industries. According to a report by the American Society of Civil Engineers, the aging infrastructure in the United States necessitates innovative solutions; more than 240,000 water main breaks occur each year due to pipe deterioration. No dig pipe repair offers a viable alternative to traditional methods, significantly reducing excavation time and costs while minimizing surface disruption. Industry expert Dr. Emily Carter, a leading consultant on trenchless technology, emphasizes the method's advantages, stating, "No dig pipe repair not only enhances the longevity of piping systems but also preserves the integrity of urban landscapes."

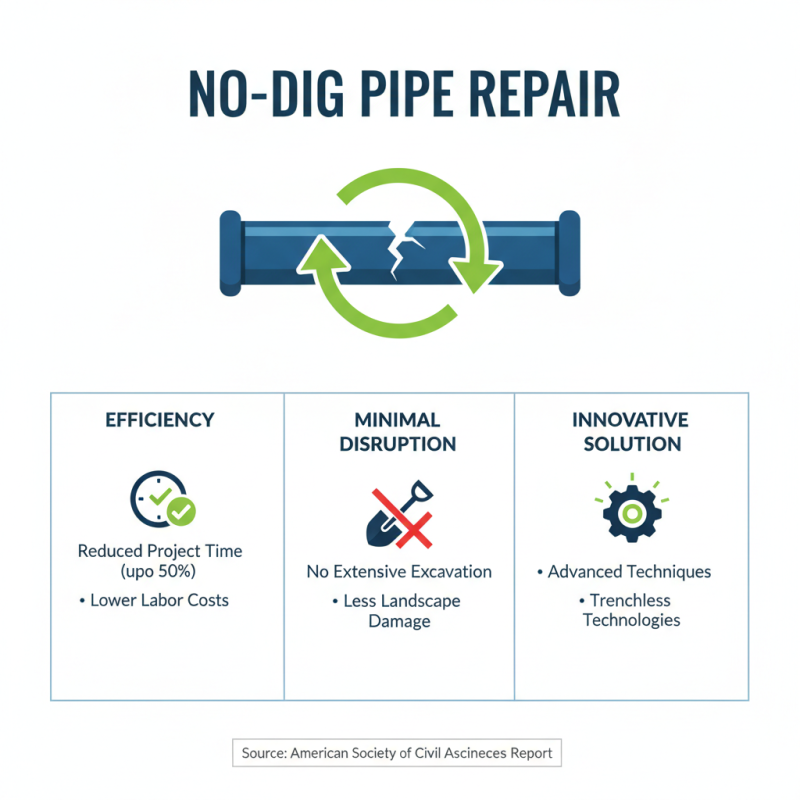

The growing adoption of no dig pipe repair can be attributed to its efficiency and the pressing need for sustainable infrastructure solutions. As urban areas continue to expand, the demand for minimal-impact repairs is critical to both economic viability and environmental preservation. Research indicates that utilizing no dig techniques can lead to repair durations that are up to 50% faster than conventional methods, which is crucial for municipalities and service providers aiming to reduce downtime and improve service reliability. The successful implementation of these methods hinges on a comprehensive understanding of the technology and best practices, ensuring that lasting results are achievable for various pipeline systems worldwide.

Understanding No Dig Pipe Repair: An Overview of Techniques

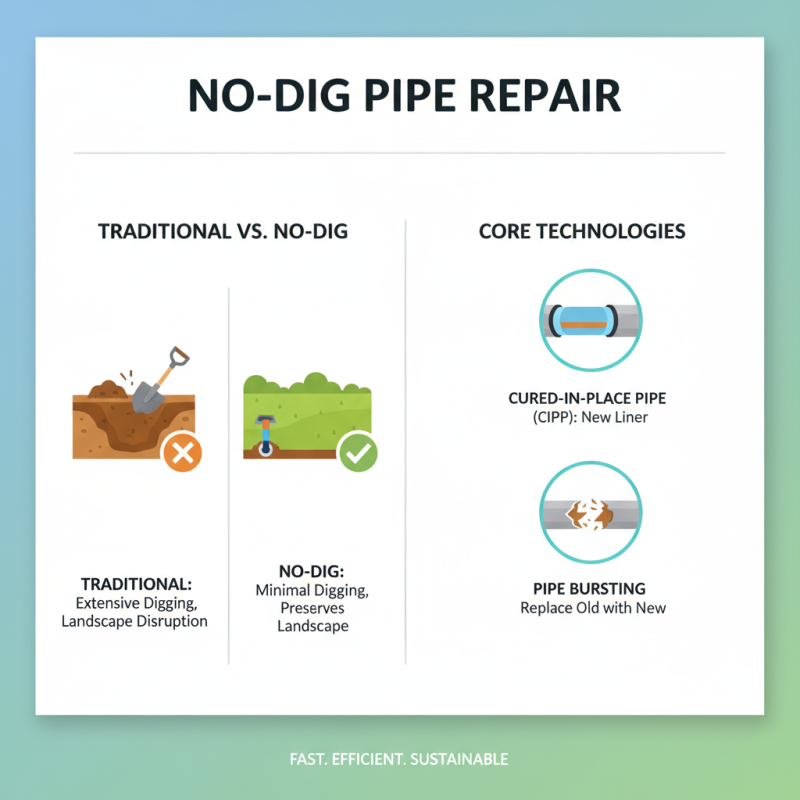

No dig pipe repair is an innovative technique designed to fix pipelines without the need for extensive digging. This method preserves the landscape and minimizes disruption, making it an attractive option for both residential and commercial applications. The core principle of no dig pipe repair revolves around the use of advanced technologies, such as trenchless methods, to repair or replace damaged pipes in situ. Such approaches include cured-in-place pipe (CIPP) lining and pipe bursting, each tailored to address specific types of damage while ensuring the integrity of the existing infrastructure.

CIPP lining involves the insertion of a resin-saturated felt tube into the existing pipe. Once in place, the tube is inflated and cured, typically with heat or UV light, creating a new, durable inner lining that seals off leaks and restores pipe function. Conversely, pipe bursting entails breaking apart the damaged pipe while simultaneously pulling a new pipe into place. This technique is especially effective for severely damaged or collapsed pipes, providing a seamless transition to a new pipeline without the mess of traditional digging. Both methods not only extend the lifespan of the plumbing system but also significantly reduce repair time and costs, making no dig pipe repair a wise choice for effective and lasting results.

Key Benefits of No Dig Pipe Repair Compared to Traditional Methods

No dig pipe repair offers several key benefits compared to traditional methods, making it an attractive choice for many property owners and contractors. One of the primary advantages is the minimal disruption it causes to the surrounding landscape. Traditional repair methods often involve extensive excavation, which can lead to damage to gardens, driveways, and other structures. In contrast, no dig techniques, such as pipe relining or trenchless technology, allow for repairs to be conducted with little to no visible disturbance, preserving the integrity of the property.

Another significant benefit of no dig pipe repair is its cost-effectiveness over time. While the initial investment may vary depending on the specific technology used, the long-term savings are compelling. No dig methods generally require fewer labor hours and reduce the need for extensive restoration work post-repair. Additionally, since these methods often result in a more durable solution, the likelihood of future repairs is diminished. This longevity translates into lower maintenance costs and decreased hassle for property owners, making no dig pipe repair a smart financial decision.

Benefits of No Dig Pipe Repair Compared to Traditional Methods

Step-by-Step Process of Performing No Dig Pipe Repair

No dig pipe repair is an innovative solution gaining traction in the plumbing industry due to its efficiency and minimal disruption. The process involves specialized techniques that allow for the repair or replacement of pipes without the need for extensive excavation. According to a report by the American Society of Civil Engineers, the implementation of trenchless technologies can reduce project time by up to 50%, significantly lowering labor costs and minimizing disturbance to surrounding areas.

The step-by-step process begins with an initial assessment of the pipe condition using advanced diagnostic tools such as video inspection systems. This allows technicians to identify the specific issues that need addressing, whether it be corrosion, leaks, or blockages. Once the problem is localized, a flexible liner is inserted into the damaged pipe. This liner is then inflated and cured, creating a new pipe within the existing one. Industry data suggests that this method can extend the lifespan of damaged pipes by up to 50 years, all while maintaining optimal flow capacity.

Finally, post-repair inspections are crucial to ensure the longevity of the repair. Comprehensive evaluations help verify the integrity of the new lining and confirm that any abnormalities have been resolved. Research indicates that proactive maintenance strategies, including regular inspections of trenchless repairs, can enhance the success rate of these interventions, ensuring durability and effectiveness in the long term.

Essential Tools and Materials Required for No Dig Pipe Repairs

No dig pipe repair is a revolutionary method that minimizes disruption while delivering lasting results. To ensure a successful repair, it's essential to have the right tools and materials. Key items include a trenchless pipe repair kit, which typically consists of resin, reinforcing fabric, and a suitable applicator. According to a study by the American Society of Civil Engineers, trenchless technologies are gaining traction, with over 60% of municipalities adopting these non-invasive methods for pipe repairs, demonstrating both cost-effectiveness and efficiency.

Additionally, having safety gear like gloves and goggles is vital for protecting yourself during the repair process. A video inspection camera can be invaluable to assess pipe conditions before starting repairs. Industry reports indicate that using such technologies can reduce excavation time by up to 70%, making the repair process not only faster but also more environmentally friendly.

Tips for a successful no dig pipe repair include: first, ensure the area is clear of obstacles to allow space for the repair equipment. Second, pre-inspect the pipe to identify specific issues and select the appropriate method for repair. Lastly, always follow manufacturer instructions carefully to achieve optimal results. Adhering to these tips will enhance the effectiveness of your no dig pipe repair, leading to durable outcomes.

How to Successfully Perform No Dig Pipe Repair for Lasting Results - Essential Tools and Materials Required for No Dig Pipe Repairs

| Tool/Material | Description | Purpose | Quantity Required |

|---|---|---|---|

| Pipe Cutter | A tool used to cut pipes cleanly and accurately. | To prepare the pipe ends for repair. | 1 |

| Epoxy Resin | A two-component adhesive used for pipe repairs. | To bond and seal the repair area. | 1 kit |

| Patching Fabric | A strong fabric used to reinforce repairs. | To provide additional strength to the repair. | 1 roll |

| Shovel | A tool for digging around pipe locations. | To expose the pipe without extensive digging. | 1 |

| Safety Gear | Includes gloves, goggles, and masks. | To ensure worker safety during repairs. | 1 set |

Industry Success Rates: Data Supporting No Dig Pipe Repair Effectiveness

Recent industry reports have shown that no dig pipe repair methods have significant success rates, leading to their increasing adoption in the plumbing and utility sectors. According to a survey conducted by the American Water Works Association (AWWA), nearly 80% of repairs completed using trenchless technology achieved long-term effectiveness, minimizing the need for future interventions. This impressive data underscores the transformative impact of no dig techniques on maintaining water and sewer systems efficiently while reducing surface disruption.

Additionally, a comprehensive study by the National Association of Sewer Service Companies (NASSCO) revealed that projects utilizing no dig pipe repair methods not only lowered labor costs by up to 30% but also decreased repair times by approximately 50%. This is particularly advantageous for municipalities aiming to improve service reliability while adhering to budget constraints. With such compelling statistics backing their effectiveness, no dig pipe repair methods are poised to redefine industry standards and practices, offering sustainable solutions for aging infrastructure challenges.

Related Posts

-

Complete Guide to Efficient CIPP Pipe Repair Techniques for Modern Infrastructure

-

Why No Dig Pipe Repair is the Future of Sustainable Plumbing Solutions

-

Unlocking the Advantages of No Dig Sewer Repair for Modern Infrastructure

-

Exploring the Future of Sewer Pipe Sleeve Innovations at the 138th Canton Fair 2025: Industry Trends and Market Growth

-

2025 Top Solutions for Internal Pipe Repair: Innovations and Best Practices

-

Top 5 Effective Methods for Pipe Repair Without Digging for Homeowners