What is an internal pipe repair sleeve and how does it work?

In the world of pipeline maintenance, the "internal pipe repair sleeve" has emerged as a vital solution. This innovative technology is designed to restore the integrity of damaged pipes. According to the Water Research Foundation, about 30% of water infrastructure experiences significant deterioration, leading to leaks and failures. The internal pipe repair sleeve effectively addresses this challenge.

Expert in pipeline repairs, Dr. John Marks, states, “The internal pipe repair sleeve offers a quick, efficient fix for compromised structures.” This technology utilizes a durable, flexible material that adheres to the original pipe. It forms a protective layer, sealing leaks and preventing further damage. Installation is often completed within hours, minimizing disruption.

However, while the internal pipe repair sleeve is beneficial, it is not without limitations. It may not resolve severe structural issues. Over time, some users have reported difficulties with adhesion. As the industry evolves, ongoing research is necessary to enhance its effectiveness and reliability. Understanding these nuances is crucial for making informed decisions in pipeline repairs.

Definition of Internal Pipe Repair Sleeve

An internal pipe repair sleeve is a specialized tool designed to mend damaged pipes from the inside. This method is often preferred for its efficiency and minimal disruption to existing systems. Internal pipe repair sleeves are typically made from durable materials, ensuring a strong bond with the existing pipe structure. They can seal leaks and prevent further damage effectively.

Installing an internal pipe repair sleeve involves first cleaning the damaged area. Once cleaned, the sleeve is inserted and expanded to fit snugly against the inner surface of the pipe. This method is less invasive than traditional repairs, which often require excavation or extensive work. However, it’s important to assess whether the damage is suitable for this type of repair.

Tips: Always inspect the area thoroughly before applying the sleeve. If there are multiple cracks or severe corrosion, a repair sleeve may not be the best option. Consider the pipe material and thickness when choosing a sleeve. Sometimes a sleeve might not provide a permanent solution. It’s advisable to monitor the condition of the repair over time. Regular checks can prevent future issues and ensure the system remains functional.

Types of Internal Pipe Repair Sleeves

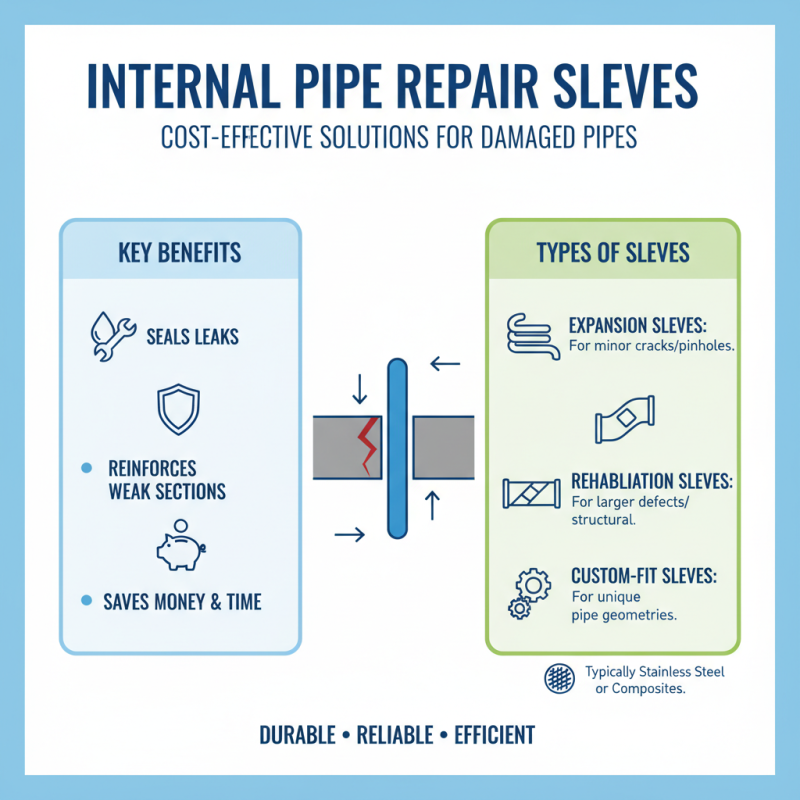

Internal pipe repair sleeves provide a cost-effective solution for damaged pipes. Various types exist, each suited for specific scenarios. These sleeves are typically made of durable materials like stainless steel. They can effectively seal leaks and reinforce weakened sections of pipes.

One common type is the mechanical sleeve. It uses internal clamps to secure around the damaged area. Research indicates that such sleeves can restore up to 90% of the original pipe strength. Another option is the epoxy-coated sleeve, designed for pipes susceptible to corrosion. This kind can prevent further deterioration, extending the pipe's lifespan.

A study revealed that nearly 30% of municipal water systems deal with aging infrastructure. Innovative solutions like internal repair sleeves can mitigate these issues efficiently. However, installation requires skilled labor. Improper fitting could lead to future leaks or failures. Therefore, while these sleeves are an excellent choice, they demand careful consideration.

Installation Process of Internal Pipe Repair Sleeves

Internal pipe repair sleeves are essential for maintaining the integrity of pipelines. The installation process of these sleeves is crucial. It begins with cleaning the damaged pipe section. Dirt and debris can hinder the sleeve's effectiveness. A thorough inspection is needed to assess the damage's extent. The right materials must be selected based on the pipe type and damage size.

Once the cleaning is done, a fitting sleeve is prepared. It's often made of strong, flexible materials. This helps in making a tight fit, ensuring it can withstand pressure. The technician should carefully align the sleeve with the damaged area. If not done correctly, leaks may occur after installation. After positioning, the sleeve is secured with clamps or adhesive. This process can take hours, depending on the damage severity.

Statistics suggest that improper installation can lead to a 30% higher chance of future repairs. Data indicates that many fail to consider long-term ramifications. Regular inspections after installation are essential. They can help identify potential issues before they escalate. Inadequate attention to detail during the installation could result in costly consequences later on.

Benefits of Using Internal Pipe Repair Sleeves

Internal pipe repair sleeves are essential for addressing issues within various piping systems. These sleeves provide significant benefits when it comes to maintenance and repair. One of the key advantages is their ability to restore the integrity of damaged pipes without the need for extensive excavation. According to a report from the American Society of Civil Engineers, routine maintenance can reduce repair costs by up to 30%. This is particularly important for aging infrastructure.

Using internal pipe repair sleeves can extend the life of a pipeline. They can seal leaks effectively, reducing the risk of future damage. A study revealed that 85% of repairs completed with these sleeves show a marked improvement in pipeline performance. They are often made from high-strength materials, making them suitable for various conditions. Yet, it’s crucial to ensure that the correct fitting and installation procedures are followed. If improperly installed, the sleeves might not function as intended, highlighting the need for skilled application.

Additionally, the process of using internal sleeves is often less disruptive than traditional methods. However, some installations have reported early failures due to environmental factors. This indicates the importance of thorough assessment and preparation before implementation. While internal pipe repair sleeves offer many advantages, careful consideration is necessary to maximize their efficiency and longevity.

Common Applications and Limitations of Internal Pipe Repair Sleeves

Internal pipe repair sleeves are used for fixing defects within pipelines. They provide a quick and effective solution. However, their applications come with specific limitations that users should consider.

Commonly, these sleeves are used in water and wastewater pipes. They can seal leaks caused by corrosion or minor cracks. In industrial settings, internal sleeves can extend the life of aging infrastructure. Yet, they may not address severe structural issues. Users should inspect the pipe thoroughly before applying these sleeves. If the damage is too extensive, a full replacement might be necessary.

One significant limitation of repair sleeves is their installation. It requires precise handling and can be difficult in tight spaces. Improper installation leads to further issues down the line. Additionally, environmental factors can affect their durability. Users must weigh these concerns before deciding. Ultimately, while internal repair sleeves offer convenience, they are not a one-size-fits-all solution. Each situation demands careful analysis.

What is an internal pipe repair sleeve and how does it work? - Common Applications and Limitations of Internal Pipe Repair Sleeves

| Aspect | Details |

|---|---|

| Definition | An internal pipe repair sleeve is a device used to repair damaged or leaking pipes from the inside. |

| Functionality | It works by being inserted into the damaged section of the pipe, effectively sealing the leak and restoring structural integrity. |

| Materials Used | Common materials for internal pipe repair sleeves include stainless steel, epoxy-coated steel, and composite materials. |

| Common Applications | Water and wastewater pipelines, industrial piping systems, and oil and gas pipelines. |

| Advantages | Quick installation, minimal disruption, and cost-effective compared to complete pipe replacement. |

| Limitations | Not suitable for severely corroded or damaged pipes, and the effectiveness may depend on the installation quality. |

Related Posts

-

Ultimate Guide to Effective Pipe Sleeve Repair Solutions for Global Procurement

-

How to Effectively Repair Your Sewer Line Without Digging for Long Lasting Results

-

2025 Top 5 Home Sewer Line Repair Solutions: Expert Insights & Cost Analysis

-

Top Tips for Pipe Repair Without Digging You Need to Know

-

2026 Best Home Sewer Line Repair Tips and Common Problems?

-

How to Choose the Right Sewer Pipe Sleeve for Your Plumbing Needs