Top 10 Essential Tips for Effective Sewer Line Sleeve Repair Techniques

In the realm of plumbing maintenance, effective sewer line sleeve repair techniques are becoming increasingly crucial for homeowners and professionals alike. According to James Carter, a renowned expert in sewer rehabilitation, “Understanding the nuances of sewer line sleeve repair can significantly extend the life of your drainage system while minimizing costly excavation.” This underscores the importance of employing the right methods in effectively managing sewer line issues.

As the demand for efficient and non-invasive repair solutions grows, mastering the essential tips for sewer line sleeve repair becomes vital. These techniques not only optimize the performance of sewage systems but also enhance their longevity, saving both time and resources. In the following sections, we will delve into the top ten crucial strategies that every plumbing professional should consider when embarking on a sewer line sleeve repair project, ensuring that each process is executed with precision and care. By integrating expert insights and proven practices, we can navigate the complexities of sewer line maintenance with confidence and expertise.

Understanding the Basics of Sewer Line Sleeve Repair Techniques

Sewer line sleeve repair techniques have gained prominence in recent years due to their efficiency and effectiveness in mitigating extensive damages. The fundamentals of this method involve inserting a snug-fitting sleeve into the damaged section of a sewer line, which acts as a new pipe within the old one. A report by the National Association of Sewer Service Companies highlights that trenchless technology, including sleeve repairs, can reduce labor costs by 30-50% compared to traditional excavation methods, making it an appealing option for both homeowners and service providers.

Understanding the basic steps involved in the sleeve repair process is crucial for ensuring successful outcomes. Initially, the damaged pipe section is inspected using advanced camera technology to determine the extent of deterioration. After this assessment, the technician prepares the area and positions the sleeve, which is typically made from a durable, corrosion-resistant material. Once in place, a resin is activated, allowing it to harden and bond with the existing pipe, restoring structural integrity. According to a study from the American Society of Civil Engineers, proper implementation of these techniques can extend the lifespan of a sewer system by up to 50 years, demonstrating the long-term benefits of embracing advanced repair methods.

Top 10 Essential Tips for Effective Sewer Line Sleeve Repair Techniques

Identifying Common Issues That Require Sleeve Repair

Identifying common issues that necessitate sleeve repair on sewer lines is crucial for effective maintenance and long-term infrastructure health. One prevalent issue is pipe corrosion, which can significantly weaken the structural integrity of sewer lines. According to a report by the Underground Construction Technology International Conference, nearly 50% of sewer lines exhibit signs of corrosion due to factors such as age, soil chemistry, and environmental conditions. This deterioration often leads to leaks, root intrusion, and inflow and infiltration (I&I) problems, making timely sleeve repairs essential.

Another common concern is joint displacement, caused by ground movement or shifting soil. A study published in the Journal of Pipeline Engineering notes that improperly aligned joints can lead to significant wastewater loss and increased treatment costs, sometimes exceeding millions of dollars annually for municipalities. Additionally, blockages due to grease buildup or foreign objects can create pressure that leads to cracks or breaks in the sewer line. Addressing these issues through sleeve repairs not only prevents further damage but also enhances the efficiency of the sewage system, ensuring that cities can meet growing demands while maintaining environmental standards.

Essential Tools and Materials for Successful Sleeve Installation

When it comes to effective sewer line sleeve repair, having the right tools and materials is crucial for ensuring a successful installation. According to the National Association of Sewer Service Companies (NASSCO), utilizing high-quality materials can significantly increase the longevity and effectiveness of repair work. Essential tools such as a sewer inspection camera are invaluable for accurately diagnosing the state of the pipes before the repair begins, allowing for precise targeting of problem areas. A recent industry report highlighted that employing advanced camera technology can reduce repair time by up to 30%, minimizing disruption and costs.

In addition to inspection tools, a proper set of installation materials is imperative for the integrity of the sleeve repair. For optimal results, it's recommended to use materials that are resistant to corrosion and capable of withstanding varying pressure levels within the sewer system. A study published by the American Society of Civil Engineers suggests that using specialized epoxy resins can enhance the bond strength of the sleeve, resulting in a more reliable repair that lasts longer than traditional methods. Furthermore, having safety equipment on hand, such as gloves and goggles, ensures that the installation process is not only efficient but also secure for the personnel involved. These components are foundational to executing successful sewer line sleeve repairs, reflecting the industry's commitment to safety and effectiveness.

Step-by-Step Process for Implementing Sleeve Repairs

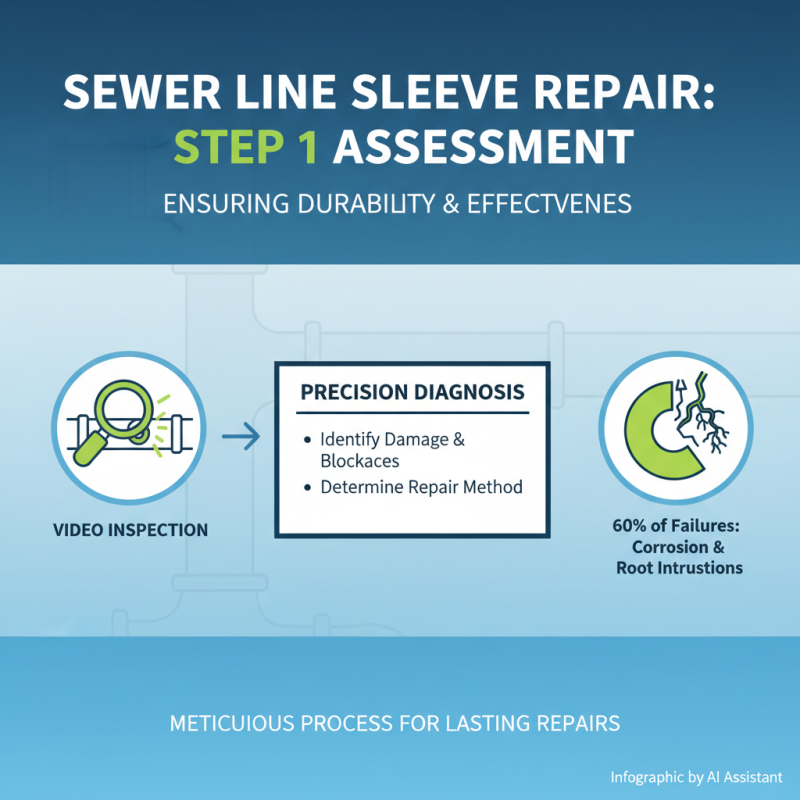

When it comes to implementing sleeve repairs for sewer lines, following a meticulous step-by-step process is crucial for ensuring durability and effectiveness. First, assess the sewer line’s condition using advanced technologies such as video inspection, which allows for precise identification of damage, blockages, or other issues. According to industry reports, nearly 60% of sewer line failures are due to years of corrosion and root intrusions. This initial assessment will guide the decision on the most effective sleeve repair method to apply.

Once you’ve identified the problem, the next step involves cleaning the affected area. Techniques such as hydro jetting can remove buildup and descaling, which is critical as even minor debris can significantly affect the adhesive process of the sleeve repair. Post-cleaning, the sleeve material—typically a resin-impregnated felt or fiberglass fabric—is positioned into the existing sewer line. An effective curing process, often achieved through inversion or inflation methods, is essential to ensure that the sleeve bonds properly with the existing pipe. Industry data indicates that properly executed sleeve repairs can extend the life of sewer lines by up to 50 years, providing a cost-effective alternative to traditional replacement methods.

Maintenance Tips to Extend the Life of Sewer Line Sleeves

Maintaining the integrity of sewer line sleeves is essential for ensuring their longevity and preventing costly repairs. Regular inspections and appropriate maintenance strategies can significantly extend the life of these systems. According to a report from the American Society of Civil Engineers (ASCE), over 30% of the nation's sewer systems are in poor condition due to neglect and lack of maintenance. By adopting a proactive maintenance schedule, homeowners and operators can reduce the risk of premature failures and extend the lifespan of sewer infrastructure.

One effective approach to maintaining sewer line sleeves is regular cleaning. Accumulation of debris and buildup of grease can lead to blockages, which not only impair the sewer's function but can also cause sleeve damage. A study published in the Journal of Environmental Engineering found that implementing routine pipe cleaning can enhance the lifespan of sewer lines by up to 50%. Additionally, using technology such as video inspection allows for early detection of problems, enabling targeted repairs before they escalate. Implementing a combination of routine cleanings and advanced monitoring techniques fosters a thoughtful maintenance regime that will help keep sewer line sleeves operational for decades to come.

Top 10 Essential Tips for Effective Sewer Line Sleeve Repair Techniques

| Tip Number | Repair Technique | Description | Benefits |

|---|---|---|---|

| 1 | Cleaning | Thoroughly clean the sewer line before any repairs. | Prevents contamination and ensures proper adhesion. |

| 2 | Inspection | Use a camera to inspect the condition of the sewer line. | Identifies problematic sections before repair. |

| 3 | Material Selection | Choose appropriate sleeve materials for the repair. | Enhances durability and compatibility with existing pipes. |

| 4 | Proper Sealing | Ensure tight seals at joint connections. | Minimizes leaks and improves the reliability of repairs. |

| 5 | Cure Time | Allow adequate curing time for the sleeve materials. | Ensures maximum strength and longevity of the repair. |

| 6 | Regular Maintenance | Schedule regular inspections and maintenance checks. | Prevents major issues and extends the life of the sleeve. |

| 7 | Avoid Corrosive Chemicals | Use non-corrosive products in the sewer line. | Protects the integrity of the sleeve and pipe materials. |

| 8 | Monitor Water Flow | Keep an eye on the flow rates post-repair. | Identifies potential blockages or weaknesses early. |

| 9 | Documentation | Keep detailed records of repairs and maintenance. | Helps track performance and plan future work. |

| 10 | Professional Help | Utilize professional services for complex repairs. | Ensures quality workmanship and lasting results. |

Related Posts

-

Creative Applications of Sewer Pipe Sleeve Repair Techniques

-

Creative Options for Sewer Repair Without Digging Methods You Should Consider

-

Innovative Approaches to Sewer Repair Without Digging A Comparative Analysis of Efficiency and Cost

-

Unlocking the Advantages of No Dig Sewer Repair for Modern Infrastructure

-

How to Effectively Use Sewer Pipe Sleeve Repair for Long-Lasting Solutions

-

7 Best Reasons to Choose CIPP Sewer Repair for Your Next Infrastructure Project