How to Effectively Resurface Pipes for Long Lasting Durability and Performance

In the field of infrastructure maintenance, the importance of pipe resurfacing cannot be overstated. According to a report by the American Society of Civil Engineers, nearly 30% of our nation's pipeline infrastructure is in need of significant repair or replacement, underscoring the urgency to adopt effective resurfacing techniques that extend the lifespan of existing pipes. Pipe resurfacing is a cost-effective alternative to complete pipe replacement, allowing for enhanced durability and performance while reducing the environmental impact associated with construction waste.

Experts emphasize the vital role that innovative resurfacing methods play in the longevity of pipeline systems. "Timely resurfacing not only prevents leaks and failures but also saves municipalities and industries significant costs in the long run," notes Dr. Jennifer M. Taylor, a leading authority on infrastructure resilience. Her insights reflect a growing consensus in the industry that proactive maintenance strategies, such as pipe resurfacing, are essential in meeting both economic and sustainability goals. By embracing new technologies and best practices, stakeholders can ensure that their pipes remain resilient against the harsh demands of everyday use.

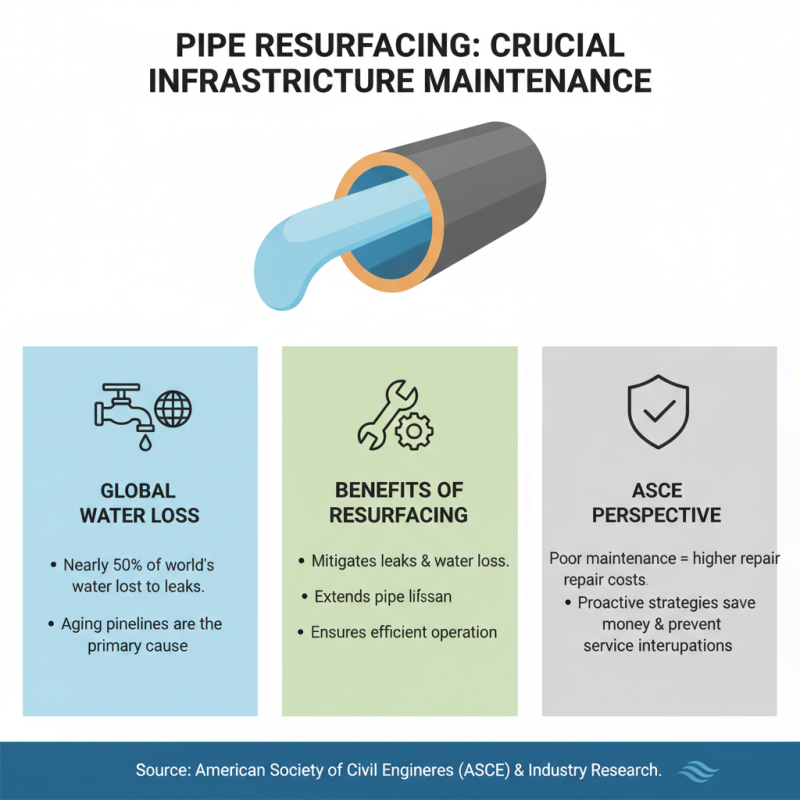

Understanding the Importance of Pipe Resurfacing in Infrastructure Maintenance

Pipe resurfacing is a crucial aspect of infrastructure maintenance, particularly for aging water and sewer systems. Research indicates that nearly 50% of the world’s water supply is lost due to leaks in aging pipelines. Proper resurfacing techniques can help mitigate these losses, extending the lifespan of pipes and ensuring efficient operation. The American Society of Civil Engineers (ASCE) reports that poorly maintained infrastructure can lead to increased repair costs and service interruptions, emphasizing the significance of proactive maintenance strategies like resurfacing.

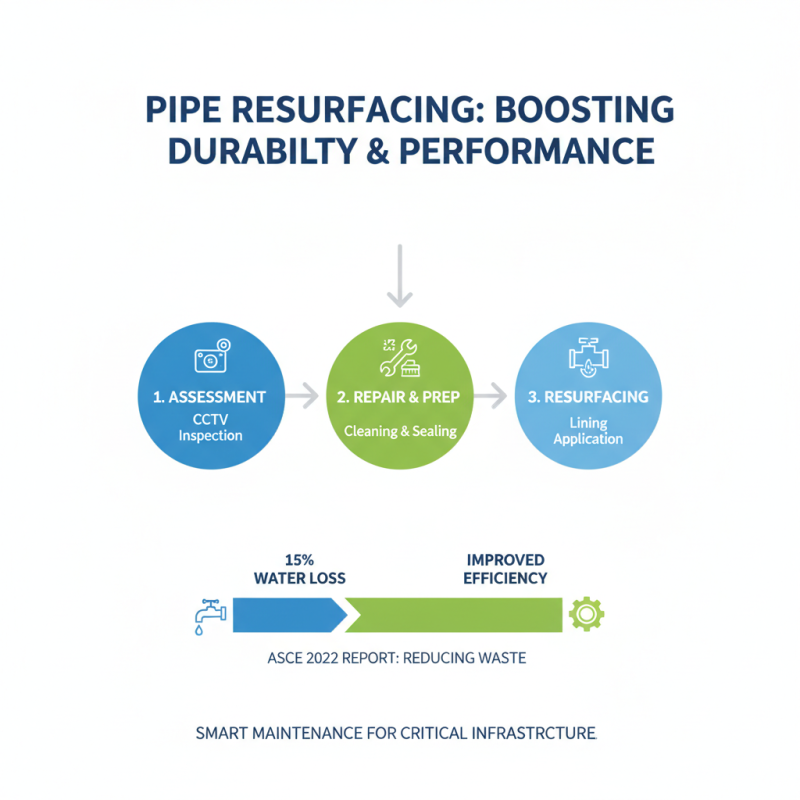

Tips for effective pipe resurfacing include thoroughly assessing the condition of the pipes before starting work. Use advanced inspection technologies, such as CCTV cameras, to identify specific areas of wear or damage. It is also essential to choose the right resurfacing materials that match the pipe material for better adhesion and longevity. Proper application techniques not only enhance durability but also improve performance, reducing the likelihood of future leaks or failures.

Lastly, regular monitoring post-resurfacing is vital. Establish a routine inspection schedule to track the condition of the resurfaced pipes. This will help catch any emerging issues early and maintain optimal performance throughout the lifespan of the infrastructure. Implementing these practices can lead to a significant reduction in maintenance costs and enhance the overall reliability of pipeline systems.

Key Factors Affecting the Durability of Resurfaced Pipes

The durability of resurfaced pipes is influenced by several key factors that must be meticulously analyzed to ensure long-lasting performance. A 2021 report from the American Society of Civil Engineers (ASCE) highlighted that improper surface preparation can lead to premature failure, revealing that up to 60% of resurfaced pipes showed signs of degradation within five years due to inadequate initial treatments. This underscores the importance of thorough cleaning and surface profiling before applying resurfacing materials. Pipe surface conditions such as rust, deformation, and existing defects critically impact adhesion and the overall longevity of the new surface.

Moreover, the choice of resurfacing materials plays a crucial role in durability. According to a study published in the Journal of Pipeline Engineering, high-performance polymer-based coatings can enhance the life expectancy of resurfaced pipes by up to 40% compared to traditional methods. This improvement is largely due to the superior chemical resistance and flexibility of these advanced materials, which allow them to withstand various environmental stresses over time. Additionally, factors like environmental conditions, temperature fluctuations, and the physical stresses from internal flow also significantly dictate how well resurfaced pipes perform. By considering these variables, engineers can optimize their resurfacing strategies for enhanced durability and efficiency in pipeline systems.

Step-by-Step Process for Efficient Pipe Resurfacing Techniques

Resurfacing pipes is a critical maintenance procedure that can enhance their durability and performance significantly. According to a 2022 report by the American Society of Civil Engineers, approximately 15% of the nation’s water supply is lost due to pipe issues, emphasizing the need for efficient resurfacing techniques. The process begins with a comprehensive assessment of the pipe's condition, where professionals utilize advanced inspection technologies like CCTV cameras to detect any damages or irregularities. This step ensures that only the necessary areas are resurfaced, optimizing both time and resources.

Once the assessment is complete, the resurfacing process can commence. This typically involves cleaning the pipe's interior thoroughly to remove any corrosion or buildup. Techniques such as hydro jetting are effective and provide a high-pressure blast that can eliminate debris, ensuring a clean surface for adhesion. Following the cleaning stage, a suitable resurfacing material is applied, which often includes advanced epoxy compounds that bond well with existing pipe materials, offering improved resistance to wear and tear. Industry studies have shown that pipes properly resurfaced can last up to 50% longer than those that are simply repaired or left unaddressed, showcasing the long-term benefits of adopting these efficient resurfacing techniques.

Material Selection for Optimal Performance in Pipe Resurfacing

When selecting materials for pipe resurfacing, it is crucial to consider the specific requirements of the pipe system, including the type of fluid being transported, environmental conditions, and the existing pipe material. Commonly used materials for resurfacing include epoxy coatings, polymer composites, and specialized cementitious products. Each of these options offers unique benefits; for instance, epoxy coatings provide excellent adhesion and resistance to corrosion, making them suitable for various environments, while polymer composites may offer enhanced flexibility and durability for applications involving fluctuating temperatures.

Additionally, the selection process should take into account the anticipated stresses on the pipe. For high-pressure systems, materials that exhibit superior tensile strength and impact resistance are essential to ensure longevity and maintain optimal performance. Moreover, the compatibility of the resurfacing material with existing pipe conditions must be assessed to prevent issues like delamination or chemical reaction. Ultimately, choosing the right material not only extends the life of the pipes but also enhances their operational efficiency, creating a resilient structure capable of handling the demands of modern infrastructure.

How to Effectively Resurface Pipes for Long Lasting Durability and Performance - Material Selection for Optimal Performance in Pipe Resurfacing

| Material Type | Durability (Years) | Corrosion Resistance | Cost (per meter) | Installation Process Complexity |

|---|---|---|---|---|

| PVC | 25 | Low | $3 | Easy |

| HDPE | 40 | Moderate | $6 | Moderate |

| Fiberglass | 50 | High | $10 | Complex |

| Steel | 30 | High | $12 | Complex |

Industry Standards and Innovations in Pipe Resurfacing Technologies

In the realm of pipe resurfacing, adherence to industry standards is paramount for ensuring long-lasting durability and performance. According to the American Society of Mechanical Engineers (ASME), resurfacing techniques must not only restore the internal and external surfaces of pipes but also enhance their mechanical properties and corrosion resistance. Innovative materials, such as polymers and epoxy coatings, are increasingly utilized for resurfacing due to their superior bonding properties and resistance to chemical degradation. Recent reports indicate that the use of such advanced materials can increase the lifespan of pipes by up to 50%, reducing the frequency of costly replacements and repairs.

The evolution of pipe resurfacing technologies has also seen the integration of automated processes, which improve precision and efficiency. The Pipeline and Hazardous Materials Safety Administration (PHMSA) emphasizes that robotic and automated resurfacing techniques can significantly minimize human error and enhance operational safety. These technologies not only streamline the resurfacing process but also allow for real-time monitoring of structural integrity, ensuring compliance with stringent safety regulations.

The implementation of these innovations is predicted to lead to a 30% increase in productivity within the pipe maintenance sector, showcasing a promising future for infrastructure sustainability and reliability.

Related Posts

-

Revolutionizing Home Maintenance: The Scientific Benefits of Digless Pipe Repair Techniques

-

7 Essential Tips for Effective Sewer Pipe Sleeve Repair Techniques

-

Understanding Sewer Line Relining: A Comprehensive Guide to Modern Pipeline Repair Techniques

-

Ultimate Guide to Effective Pipe Sleeve Repair Solutions for Global Procurement

-

Exploring the Future of Pipe Rehabilitation: Innovations and Best Practices for Sustainable Infrastructure

-

Transforming Infrastructure: The Ultimate Guide to CIPP Pipe Repair Solutions