Top 10 Effective Techniques for Well Pipe Repair You Should Know

Well pipe repair is a critical aspect of maintaining the integrity and functionality of water supply systems across various regions. The National Ground Water Association (NGWA) estimates that approximately 15 million households in the United States rely on private wells for their water supply. As these systems age and experience wear, effective repair techniques become essential not only to ensure a consistent water flow but also to safeguard public health. Research indicates that neglected well maintenance can lead to water quality issues, which can impact more than 85% of well owners, highlighting the necessity for timely and effective well pipe repair interventions.

Moreover, according to industry reports, the cost of well pipe repair can be considerably lower when proactive measures are taken, compared to the expenses associated with complete system replacements. A survey conducted by the Water Quality Association reported that 60% of well owners spend an average of $1,500 to $3,000 on repairs, while inadequate maintenance can double these costs over time. With the growing importance of sustainable water management practices, understanding and implementing the top techniques for well pipe repair is not just beneficial but essential for ensuring long-term water quality and accessibility for communities dependent on well systems.

Understanding Common Well Pipe Issues and Their Causes

Well pipe issues can arise from various factors, impacting both functionality and water quality. Common problems include corrosion, cracks, and blockages, often resulting from environmental conditions and the type of materials used. According to a report by the National Ground Water Association, pipes that are improperly maintained can lead to significant water loss, estimated at up to 20% in certain regions. This loss not only wastes a precious resource but can also increase costs for homeowners.

Corrosion is particularly prevalent in older well pipes, especially those made from iron and steel. A study published in the Journal of Water Resources indicates that around 30% of wells constructed before 1970 experience severe corrosion, leading to compromised water quality and reduced output. Moreover, biological growth, such as bacteria and algae, can thrive in wells where infrequent maintenance occurs, contributing to blockages and further complicating repair efforts. Understanding these common issues and their causes is crucial for any homeowner relying on a well system, as proactive measures can extend the life of well pipes and ensure a consistent supply of clean water.

Essential Tools and Materials for Effective Well Pipe Repair

When it comes to effective well pipe repair, having the right tools and materials is essential to ensure a successful and lasting restoration. Start with a basic toolkit that includes a pipe wrench, adjustable pliers, and a hacksaw. These tools will help you efficiently handle various pipe sizes and types, allowing you to tackle repairs with confidence. Additionally, a quality pipe inspection camera can be an invaluable asset, enabling you to assess the condition of the pipes and identify specific issues before starting the repair process.

In terms of materials, it's crucial to have an assortment of pipe couplings, connectors, and repair clamps on hand. These components will enable you to make quick fixes and secure any damaged areas of the pipe. You should also consider having sealing tape and pipe sealants available, as they play a vital role in preventing leaks after a repair. Lastly, protective gear such as gloves and safety goggles are essential to ensure your safety throughout the repair process. Together, these tools and materials will equip you with everything you need for an effective well pipe repair.

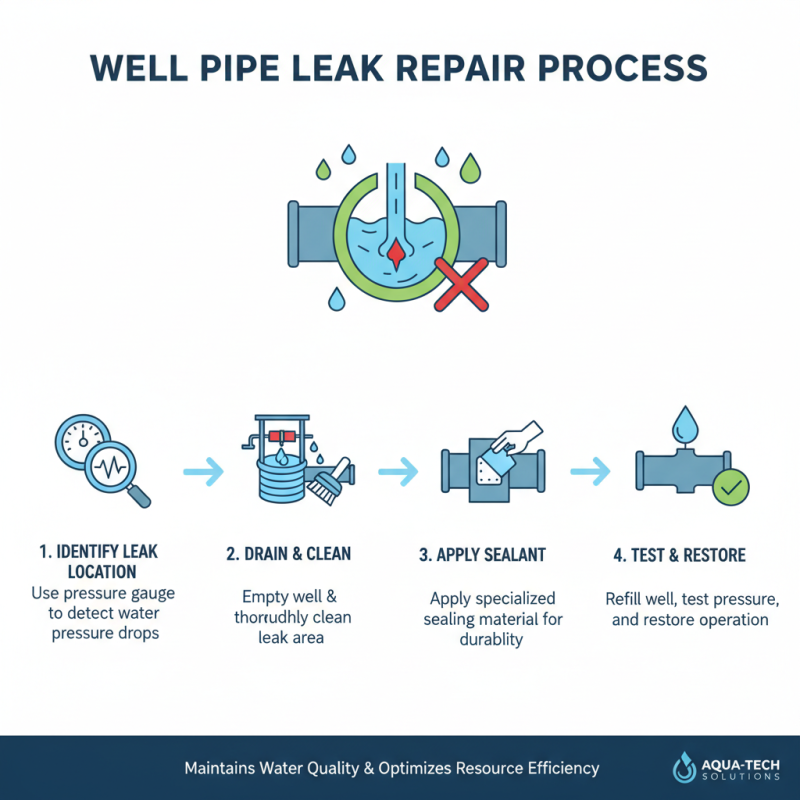

Step-by-Step Guide to Sealing Leaks in Well Pipe Systems

Sealing leaks in well pipe systems is crucial for maintaining water quality and optimizing resource efficiency. The process begins with identifying the exact location of the leak. Utilize a pressure gauge to determine fluctuations in water pressure, which can indicate a leak. Once pinpointed, the first step in the repair process involves draining the well and thoroughly cleaning the area around the leak. This ensures that any repair materials will adhere properly, creating a more durable seal.

After cleaning, you can employ a variety of techniques to seal the leak. One common method is using epoxy-based sealants that can be applied directly to the leak. This is particularly effective for small cracks. For larger leaks, consider wrapping the area with specialized repair tape designed for high-pressure applications. It's essential to follow up with a thorough inspection to ensure the repair holds and no further leaks have formed.

Tips: Always wear appropriate safety gear when working with well systems, and consider consulting with a professional if you're unsure. Regularly inspecting your well pipe systems can help catch potential issues early, preventing more significant repairs down the road. Additionally, keeping a maintenance log can help track repairs and changes in the system, allowing for better management of your well infrastructure.

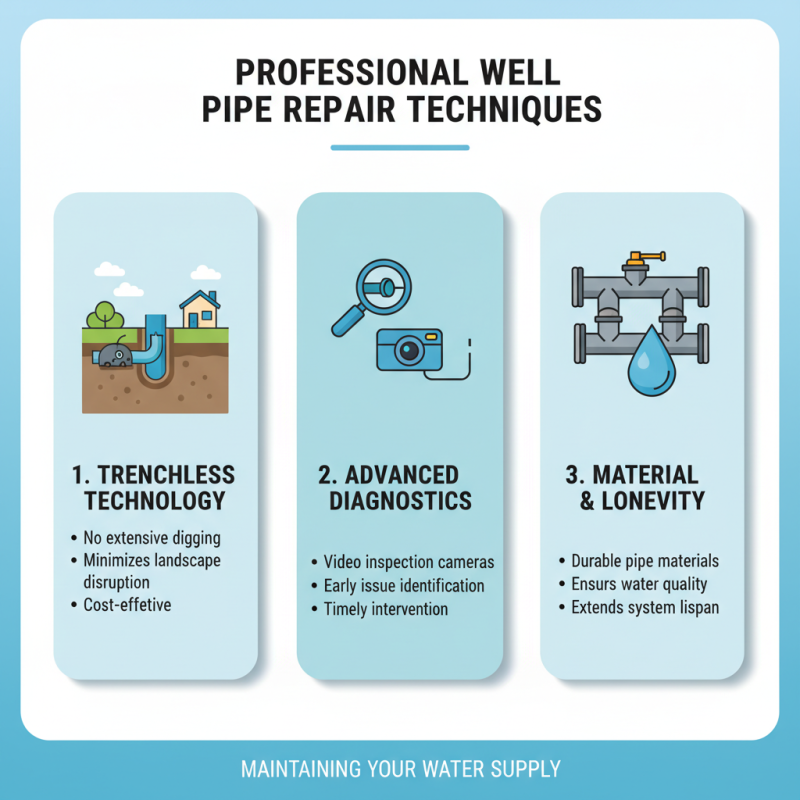

Professional Techniques for Replacing Damaged Well Pipes

When it comes to well pipe repair, understanding professional techniques for replacing damaged well pipes is crucial for maintaining water quality and ensuring the longevity of your water supply system. One effective method is the use of trenchless technology, which allows for replacement without extensive digging. This minimizes disruption to the surrounding landscape and is often a more cost-effective solution. Additionally, proper assessment of the well pipe condition and utilizing advanced tools such as video inspection cameras can identify issues early, ensuring timely intervention.

When embarking on a pipe replacement project, it’s essential to follow best practices. First, make sure to identify the right materials that are durable and corrosion-resistant to suit your specific water conditions. Secondly, always follow local regulations for well maintenance and repair to avoid future complications.

**Tips:** Always consult with a professional before starting any repair work to gain insights into the best techniques tailored for your specific situation. Regular maintenance checks can prevent major issues down the line and save you money. Consider investing in high-quality sealing materials to enhance the durability of the repair and ensure a watertight fit during replacements.

Best Practices for Preventive Maintenance of Well Pipes

Preventive maintenance of well pipes is crucial to ensure their longevity and efficient operation. One of the best practices for maintaining well pipes is to conduct regular inspections. This involves checking for signs of wear and tear, leaks, and any unusual noises that could indicate underlying issues. By identifying problems early, you can address them before they escalate into more significant repairs, ultimately saving time and money.

Another essential technique is to ensure proper filtration and water treatment. Installing appropriate filters can prevent debris and sediments from accumulating in the well pipes, which can lead to clogs and pressure issues. Moreover, conducting water quality tests periodically can help detect harmful contaminants and assist in making informed decisions on necessary treatment methods. Lastly, keeping well records of maintenance activities and the condition of the pipes will provide valuable insights over time, enabling better planning for future maintenance tasks and reinforcing the overall health of the well system.

Top 10 Effective Techniques for Well Pipe Repair

This bar chart illustrates the effectiveness of various techniques used in well pipe repair, highlighting their average success rates in percentage. The techniques include sealing leaks, replacing sections of pipe, hydro jetting, and using epoxies among others. Effective maintenance practices can significantly enhance the lifespan and functionality of well pipes.

Related Posts

-

How to Choose the Right Pipe Fixers for Your Plumbing Needs

-

Exploring the Future of Pipe Rehabilitation: Innovations and Best Practices for Sustainable Infrastructure

-

How to Effectively Repair Internal Sewer Pipes: A Comprehensive Guide

-

Creative Applications of Sewer Pipe Sleeve Repair Techniques

-

7 Best Reasons to Choose CIPP Sewer Repair for Your Next Infrastructure Project

-

Creative Options for Sewer Repair Without Digging Methods You Should Consider