How to Choose the Right Pipe Sleeve for Your Project?

Choosing the right pipe sleeve for your project can be challenging. A correct selection can enhance performance and longevity. Pipe sleeves play a crucial role in protecting pipes from environmental factors. They also prevent corrosion and moisture damage.

When selecting a pipe sleeve, consider materials, size, and purpose. Different projects require different specifications. For instance, a thicker sleeve may be necessary for high-pressure applications. Some properties might be overlooked during the selection process. It’s essential to reflect on these aspects to avoid future issues.

Visualize the project environment as you make your choice. Extreme temperatures or exposure to chemicals can impact the sleeve's effectiveness. A mismatch could lead to costly repairs down the line. Taking the time to review your options will help you make informed decisions. Ultimately, the right pipe sleeve will contribute significantly to the overall success of the project.

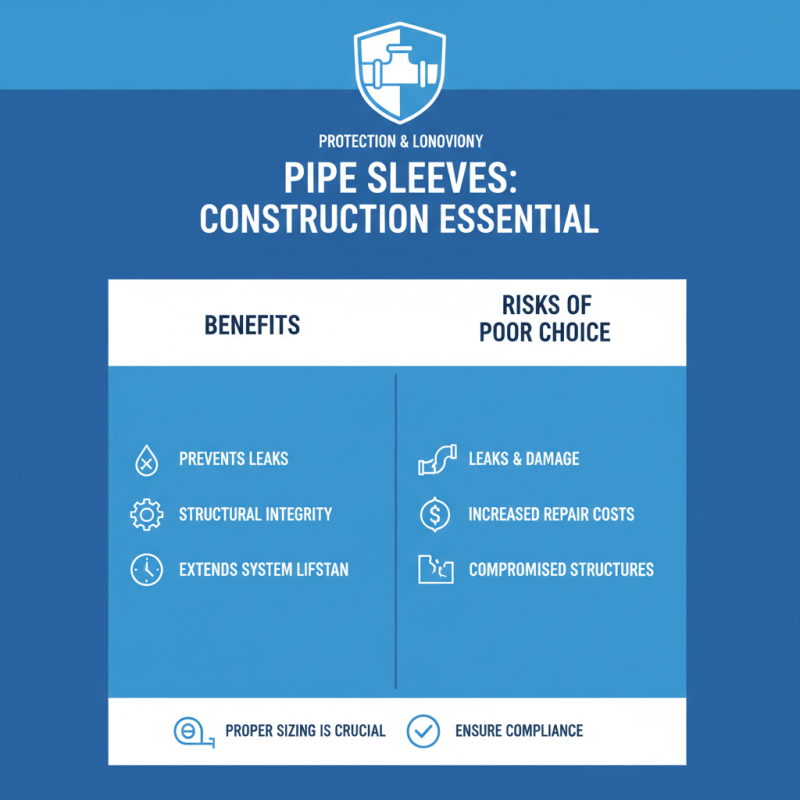

Understanding the Importance of Pipe Sleeves in Construction Projects

Pipe sleeves play a crucial role in construction projects. They protect pipes from environmental factors. This ensures the longevity of a plumbing system. In many cases, poorly chosen sleeves can lead to serious issues. For instance, using a sleeve that isn’t the right size can cause leaks. These leaks can damage surrounding structures and increase repair costs.

Selecting the right sleeve involves understanding materials and purpose. Different projects may require different sleeve types. Some materials resist corrosion, while others provide insulation. A sleeve that doesn't fit correctly can lead to inefficiencies. It can also pose safety risks. Often, project managers overlook this aspect. They may focus more on aesthetics or cost rather than durability.

Inadequate research can result in costly mistakes. Consider the environment where the sleeve will be used. Extreme weather can wear down certain materials faster. It’s essential to reflect on these details before making a decision. Sometimes, asking for expert advice can bring clarity. A little extra time spent on selection can save a lot down the road.

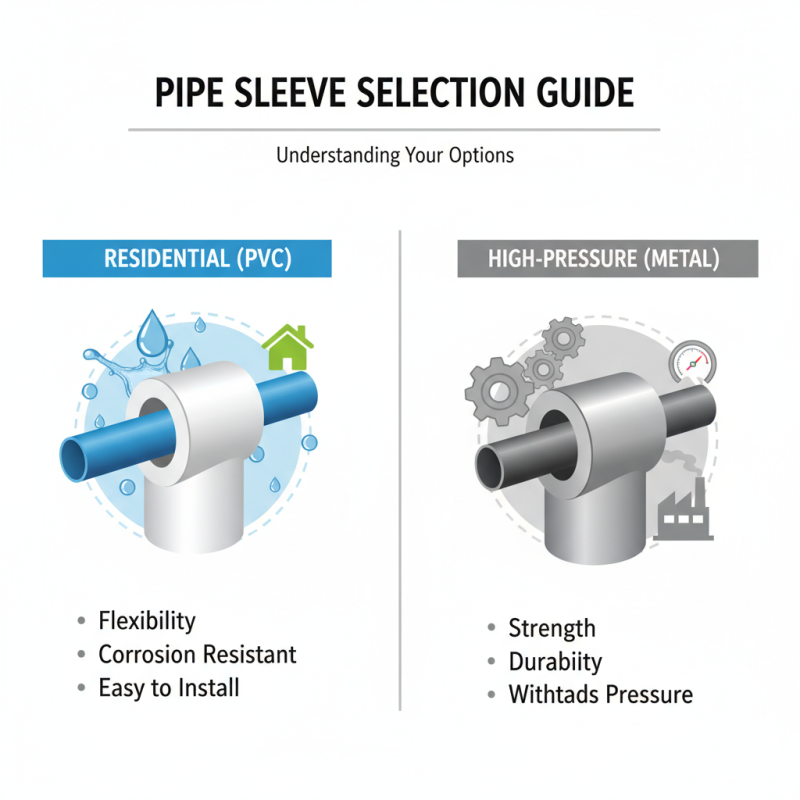

Identifying the Different Types of Pipe Sleeves Available

When selecting a pipe sleeve for your project, understanding the options is essential. Pipe sleeves come in various types, each designed for specific applications. For instance, PVC sleeves are commonly used in residential settings. They offer flexibility and resistance to corrosion. On the other hand, metal sleeves, like stainless steel, provide strength and durability. They are suitable for high-pressure systems.

Another option is rubber sleeves. These are ideal for sound insulation and vibration dampening. They are often used in industrial settings. Each type serves unique purposes and is influenced by project requirements. It's important to avoid jumping to conclusions about which sleeve is best. Inadequate knowledge may lead to costly mistakes.

Choosing the right sleeve means considering factors like environment and pressure. Sometimes, a simple sleeve might not suffice. You might need multiple layers or additional features. Be careful and research thoroughly before making decisions. Mistakes in sleeve selection can lead to leaks or failures down the line. Take your time to evaluate your needs. Choosing wisely will save you from potential issues later.

Assessing Material Compatibility for Your Specific Application

Choosing the right pipe sleeve requires understanding material compatibility. Different applications demand different materials. Factors such as temperature, pressure, and chemical exposure play a crucial role. For instance, polyester sleeves can withstand high temperatures, but may degrade in certain chemical environments. Research shows that 30% of failures in piping systems arise from improper material matching.

When selecting materials, assess the operational environment carefully. If you expect high levels of corrosion, consider using materials like stainless steel or fluoropolymers. Always refer to industry standards that outline compatibility. Organizations like ASTM provide guidelines that can be immensely helpful. Keeping in mind the specific application can save time and costs in the long run.

**Tip:** Always test material samples under real conditions before finalizing your choice.

Consider potential environmental factors that could affect performance. Extreme temperatures can lead to expansion or contraction in materials, causing damage over time. Moreover, remember that even small misalignments in compatibility can lead to larger issues.

**Tip:** Consult with experts when in doubt about material choices. A second opinion can prevent costly mistakes.

Evaluating Size, Thickness, and Length Requirements for Pipe Sleeves

Choosing the right pipe sleeve involves understanding size, thickness, and length needs. Industry reports indicate that improper sizing can lead to leaks and structural failures. Ensuring a tight fit reduces risks associated with pressure changes and temperature fluctuations. A recent survey showed that over 40% of projects faced delays due to incorrect sleeve specifications.

Thickness is another critical factor. The American Society for Testing and Materials (ASTM) suggests that sleeve thickness should be determined by the environment. For example, a thicker sleeve might be crucial in high-pressure systems. Many engineers overlook this aspect. As a result, they have to frequently replace sleeves, wasting time and resources.

Length requirements cannot be ignored either. A sleeve that is too short may not cover vital joint areas. Reports suggest that a sleeve should extend beyond the joint by at least 1 inch. However, achieving the right balance can be tricky. Some projects use overly long sleeves, which can complicate installation. Careful evaluation is essential for each project’s unique demands.

Factors to Consider: Cost, Availability, and Installation Guidelines

When selecting a pipe sleeve for your project, cost is a crucial factor. Different materials come with varying price tags. It’s vital to balance quality and affordability. For example, high-quality materials may cost more upfront but provide long-term savings. Always consider the budget constraints of your project. A less expensive sleeve might save money now but could lead to higher maintenance costs later.

Availability can also impact your choice. Not all pipe sleeves are easy to find. Research local suppliers and online options. Ensure you can source the sleeves in time to meet project deadlines. If a specific model is in short supply, it may delay your installation. Think about alternatives and their availability.

Installation guidelines should not be overlooked. Each sleeve type has unique requirements. Some may need additional tools or specific techniques. It’s important to read the installation instructions carefully. Rushing through this process can lead to mistakes. An imperfect install could result in future complications. Always plan for potential challenges that may arise during installation. Carefully assessing these factors ensures your project runs smoothly and efficiently.

How to Choose the Right Pipe Sleeve for Your Project

Related Posts

-

Unlocking the Advantages of Pipe Sleeve Solutions for Global Procurement

-

Innovative Pipe Sleeve Solutions Unveiled at the 138th Canton Fair 2025 in China

-

Understanding Sewer Line Relining: A Comprehensive Guide to Modern Pipeline Repair Techniques

-

How to Effectively Repair Sleeve Pipes: A Step-by-Step Guide

-

5 Best Internal Pipe Repair Sleeves for Reliable Water Line Solutions

-

Top 2025 Pipe Fixer Solutions to Prevent Plumbing Disasters