How to Choose the Right Pressure Pipe for Your Plumbing Needs

When it comes to selecting the appropriate pressure pipe for plumbing needs, the decision is paramount for ensuring both functionality and safety in residential and commercial systems. According to a recent report by the American Society of Civil Engineers (ASCE), the aging infrastructure in many regions has prompted a significant increase in the demand for reliable pressure pipe systems. In fact, the market for pressure pipes is projected to grow at a compound annual growth rate (CAGR) of 6.5% through 2025, highlighting the critical importance of making informed choices in this sector.

Experts emphasize the need for careful consideration when choosing pressure pipes. Dr. Emily Johnson, a leading authority in plumbing engineering, asserts, "The selection of the right pressure pipe can vastly affect not only the longevity of the system but also its operational efficiency." With diverse materials available, including PVC, HDPE, and copper, each suited for different applications and environmental conditions, understanding your specific plumbing needs is vital.

As we navigate through the process of selecting a pressure pipe, it is essential to rely on expert advice and industry standards to guarantee the best outcomes for both immediate functionality and long-term durability. This guide aims to shed light on the various factors that influence the choice of pressure pipes, helping consumers make informed decisions that meet their plumbing requirements.

Understanding the Types of Pressure Pipes Available for Plumbing

When selecting the right pressure pipe for plumbing needs, understanding the various types available is crucial. In North America, copper tubes are a popular choice, categorized into three main types: Type K, Type L, and Type M. Type K, with the thickest walls, is ideal for underground installations and has higher pressure ratings, making it suitable for water supply systems. Type L offers a balance between strength and flexibility, making it versatile for both residential and commercial plumbing. Type M, being the thinnest, is generally used for lighter applications, such as in heating systems.

Alternatively, PVC pipes have gained traction in plumbing due to their cost-effectiveness and resistance to corrosion. The PVC Pipes & Fittings Market includes various materials such as UPVC and CPVC, catering to different applications like water supply and drainage. Each material has distinct properties impacting flow efficiency and durability. It is essential to consider factors such as pressure ratings, application requirements, and environmental conditions when choosing between these pipe types to ensure the longevity and efficiency of plumbing systems.

Pressure Pipe Types and Their Applications

This chart illustrates the various types of pressure pipes commonly used in plumbing, alongside their typical applications and pressure ratings. Understanding these variables can help you choose the right pipe for your plumbing needs.

Key Factors to Consider When Selecting Pressure Pipes for Your Project

When selecting pressure pipes for plumbing needs, there are several key factors to consider that can significantly impact the effectiveness and longevity of your plumbing system. Material selection is paramount; for instance, the global HDPE pipes market is projected to reach USD 25.68 billion by 2029, highlighting the increasing popularity of HDPE due to its durability and corrosion resistance. The choice of material influences not only the cost but also the system's overall performance under pressure.

Another critical factor is compliance with industry standards, such as ASME B31.3, which ensures the safe and efficient operation of piping systems. This standard addresses various aspects of piping design and installation, reinforcing the importance of adhering to recognized guidelines to prevent safety hazards. Additionally, the expansion of markets like the U.S. PVC and CPVC pipe fittings sector, expected to grow at a CAGR of 5.8% from 2025 to 2033, illustrates the demand for reliable pipe fittings that can help maintain the integrity of plumbing systems. These considerations are essential for making informed decisions during the selection process, ultimately leading to a more efficient and durable plumbing infrastructure.

Comparing Material Properties: PVC, CPVC, and PEX Pressure Pipes

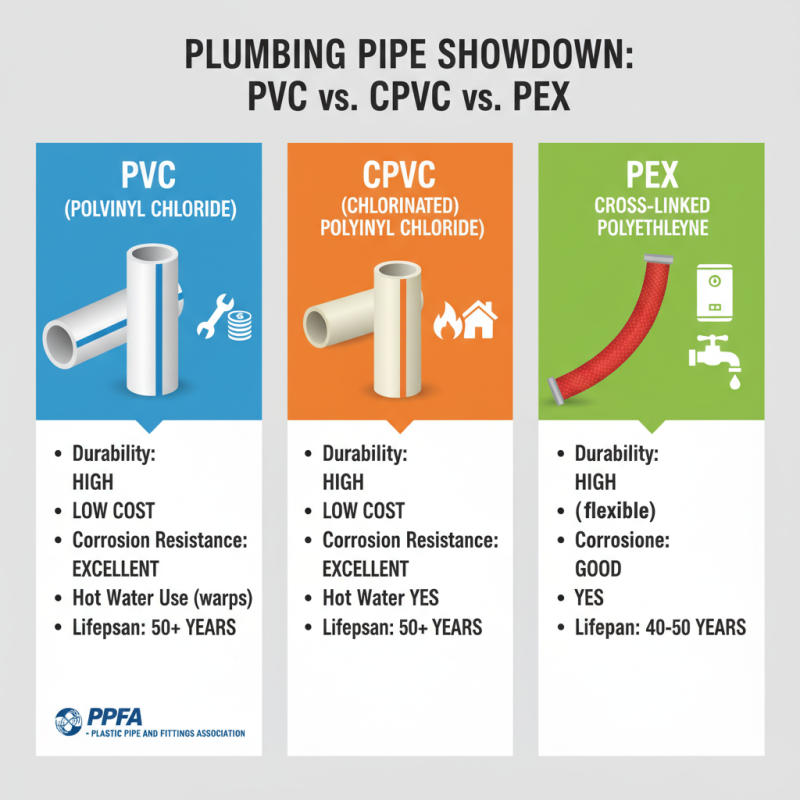

When choosing the right pressure pipe for your plumbing needs, it's essential to compare the properties of PVC, CPVC, and PEX pipes. PVC (Polyvinyl Chloride) is widely recognized for its durability, affordability, and resistance to corrosion. A report from the Plastic Pipe and Fittings Association (PPFA) highlights that PVC pipes have a lifespan of over 50 years, making them a reliable choice for both residential and commercial applications. However, PVC is not suitable for hot water systems as it can warp under high temperatures.

CPVC (Chlorinated Polyvinyl Chloride) offers an expanded temperature range, suitable for hot and cold water systems, withstanding temperatures up to 200°F. According to a study by the American Society of Plumbing Engineers (ASPE), CPVC pipes exhibit excellent resistance to scale and corrosion, making them ideal for piping systems that require hot water. Despite being slightly more expensive than PVC, the benefits in high-temperature applications justify the investment for many homeowners and contractors.

PEX (Cross-Linked Polyethylene) is another versatile option known for its flexibility and ease of installation, which can reduce labor costs significantly. PEX is resistant to freezing and bursting, with a flexibility that allows for fewer fittings and joints. A report from the Vinyl Institute notes that PEX can last up to 40 years, and its ability to maintain water quality by minimizing scale buildup is also commendable.

Tips: When selecting pressure pipes, consider the water temperature and pressure conditions of your system. For high temperatures, opt for CPVC, while PVC suffices for cold water applications. If you seek easier installation and flexibility, PEX may be the best choice. Always refer to local plumbing codes and regulations to ensure compliance.

Industry Standards and Certifications for Plumbing Pressure Pipes

When selecting the right pressure pipe for plumbing needs, understanding industry standards and certifications is crucial. Pressure pipes, particularly those made from materials like UPVC, CPVC, and flexible PVC, must meet rigorous safety and performance criteria to ensure reliability in water supply and distribution systems. Reports indicate that the PVC pipes and fittings market is projected to grow significantly, influenced by the rising demand for durable and efficient plumbing solutions across various applications.

To ensure you choose pipes that meet necessary standards, look for certifications that verify products conform to national and international guidelines. For example, pipes that comply with ASTM and ISO standards guarantee effectiveness in high-pressure applications. These industry benchmarks not only assure quality but also enhance the lifespan and efficiency of water distribution systems.

Tips: Always check the relevant standards for your specific project; this can save you from costly mistakes down the line. Additionally, evaluate the environmental impact of the materials you choose, as many contemporary options are designed to minimize waste and contribute to sustainability efforts. Lastly, consider the ease of installation and maintenance when selecting your pressure pipes, as this can significantly affect the overall performance of your plumbing system.

How to Choose the Right Pressure Pipe for Your Plumbing Needs - Industry Standards and Certifications for Plumbing Pressure Pipes

| Pipe Material | Pressure Rating (psi) | Temperature Range (°F) | Industry Standards | Common Certifications |

|---|---|---|---|---|

| PVC | Schedule 40 - 280 psi | 32°F to 140°F | ASTM D1785 | NSF 61 |

| CPVC | Schedule 40 - 400 psi | 32°F to 180°F | ASTM D2846 | NSF 14 |

| PE | SDR 11 - 160 psi | 73°F | ASTM D2239 | NSF 61 |

| Steel | Schedule 40 - 3000 psi | -20°F to 800°F | ASTM A53 | API 5L |

| Copper | Type L - 500 psi | -40°F to 400°F | ASTM B88 | NSF 61 |

Calculating Pressure Ratings and Flow Capacity for Different Pipe Sizes

When selecting the right pressure pipe for plumbing needs, understanding the pressure ratings and flow capacity is crucial. Pressure ratings are typically measured in PSI (pounds per square inch) and are determined by factors such as the pipe material and manufacturing standards. According to a report by the American Society for Testing and Materials (ASTM), PVC pipes can typically handle pressures up to 280 PSI, while CPVC pipes can withstand up to 400 PSI. It's essential to match the pipe's pressure rating with the demands of your plumbing system to avoid failures.

To accurately assess flow capacity, it's important to consider the diameter of the pipe. A 1-inch diameter pipe can typically deliver about 30 gallons per minute (GPM) at optimal pressure, while a 2-inch pipe can handle around 120 GPM. Tools like the Hazen-Williams equation can provide insights into flow pressure losses, vital for ensuring adequate system performance.

Tips:

- Always consult the manufacturer's specifications for accurate pressure ratings.

- Consider the total length of the run; longer runs may require larger diameter pipes to maintain desired flow rates.

- Factor in any fittings, valves, or bends in the plumbing system, as these can significantly impact overall flow capacity.

Related Posts

-

Exploring the Future of Sewer Pipe Sleeve Innovations at the 138th Canton Fair 2025: Industry Trends and Market Growth

-

7 Essential Tips for Efficient Water Well Repair to Boost Lifespan by 30%!

-

Understanding Sewer Line Relining: A Comprehensive Guide to Modern Pipeline Repair Techniques

-

Comprehensive Pump Repair Checklist for Efficient Plant Operations and Reduced Downtime

-

Ultimate Guide to Effective Pipe Sleeve Repair Solutions for Global Procurement

-

Why No Dig Pipe Repair is the Future of Sustainable Plumbing Solutions