Top 10 Benefits of Using Pipe Sleeves in Construction?

In the construction industry, the use of pipe sleeves is becoming increasingly important. Renowned expert David Ellison, a leading voice in construction materials, asserts, “Pipe sleeves enhance the durability and efficiency of any project.” This statement encapsulates the benefits that come with proper pipe sleeve implementation.

Pipe sleeves serve as vital components in protecting and insulating pipes from environmental factors. They prevent corrosion, reducing long-term maintenance costs. Often, problems in construction arise from neglecting these protective measures. Inadequate sleeve installation can lead to significant issues down the line.

The impact of using pipe sleeves is not only practical but also economical. These sleeves can save time and money by minimizing repairs. However, there are still misconceptions about their importance. Some professionals overlook their benefits, which can result in costly mistakes. Awareness and education about pipe sleeves can lead to more efficient construction outcomes.

Advantages of Pipe Sleeves in Construction: An Overview

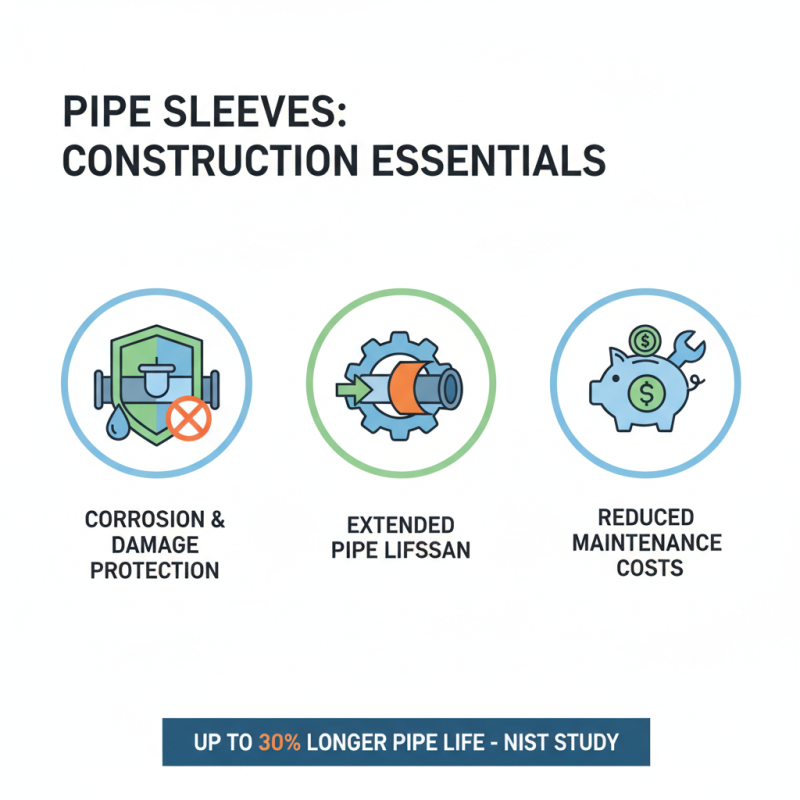

Pipe sleeves are crucial in construction for several reasons. They provide protection from corrosion, mechanical damage, and environmental factors. A study by the National Institute of Standards and Technology highlighted that using sleeves can extend the life of pipes by up to 30%. This prolongs maintenance cycles and reduces replacement costs.

Additionally, pipe sleeves offer insulation. They can improve energy efficiency by minimizing heat loss. According to the Department of Energy, insulated pipes can reduce energy consumption by 10% to 30%, leading to lower operational costs. This is particularly important in large commercial buildings where overhead costs significantly impact the bottom line.

However, not all installations are perfect. Some have found that improper sleeve fitting can lead to moisture accumulation. This could cause long-term damage. Regular inspections are necessary for ensuring functionality and effectiveness. Making these small adjustments can lead to big savings in the project lifecycle.

Enhancing Durability and Longevity of Pipes with Sleeves

Pipe sleeves play a crucial role in construction. They enhance the durability of pipes, making them more resilient to environmental challenges. By providing an additional protective layer, these sleeves prevent damage from physical impacts, corrosion, and extreme temperatures. For instance, when buried underground, pipes are susceptible to soil movement or external pressure. Sleeves can absorb some of this stress, maintaining pipe integrity longer.

However, the application of pipe sleeves is not without its challenges. Proper installation is key to maximizing their benefits. If a sleeve is poorly fitted, gaps may still allow moisture or debris to enter. This undermines the very protection the sleeve is meant to offer. Additionally, inconsistent quality in sleeve materials can lead to variations in performance. Sometimes, construction teams overlook these issues, focusing solely on speed rather than quality.

Ultimately, using pipe sleeves correctly enhances the longevity of plumbing systems. This results in lower maintenance costs and fewer outages. Investing in robust sleeves can make a significant difference. However, awareness of potential pitfalls is essential to leverage their full benefits. The effectiveness of pipe sleeves hinges on careful consideration and thorough implementation.

Improving Safety Standards in Construction through Pipe Sleeves

Construction sites often present numerous safety hazards. Pipe sleeves can play a crucial role in mitigating these dangers. They help protect exposed pipes, reducing the risk of accidents. When pipes are properly covered, workers are less likely to trip or get injured.

Using pipe sleeves also aids in temperature regulation. Insulation materials can cover pipes and prevent burns. This feature is especially vital in high-temperature environments. Despite these benefits, some construction teams neglect this aspect. They may view it as an additional cost rather than a safety investment. This mindset can lead to regrettable incidents.

Another essential aspect is the ease of maintenance. Pipe sleeves simplify inspections. Workers can easily assess damages or potential leaks. However, not all teams prioritize regular checks. This oversight can create long-term issues. Regularly scheduled maintenance should be a standard practice to ensure safety and efficiency. Embracing proper use of pipe sleeves means fostering a safer work environment for everyone on site.

Top 10 Benefits of Using Pipe Sleeves in Construction

Cost-Effectiveness of Pipe Sleeves for Construction Projects

In construction, pipe sleeves offer significant cost-effectiveness. They protect pipes from environmental stresses and mechanical damage, prolonging their life. A study by the Construction Industry Institute noted that effective pipe protection can reduce replacement costs by up to 30%. This is crucial as pipe failures can lead to unexpected delays and expenses.

Installation of pipe sleeves is relatively straightforward and quick. This efficiency can save labor costs significantly. A contractor can reduce installation time by an average of 15% by using pipe sleeves correctly. Moreover, pipe sleeves minimize the risk of leaks and corrosion, which are expensive to fix. In a recent survey, 65% of construction managers reported reduced maintenance costs when using these protective measures.

However, not all projects prioritize pipe sleeves. Some see them as an unnecessary expense upfront. This view can lead to issues later on. Ignoring the long-term benefits can cost more than initial savings. Construction teams need to weigh the immediate budget against potential future expenses. Effective budgeting is key for successful project outcomes.

Pipe Sleeves: A Solution for Temperature and Humidity Control

Pipe sleeves play a crucial role in construction, particularly for managing temperature and humidity. These protective covers insulate pipes, reducing heat loss or gain. When exposed to fluctuating temperatures, pipes can expand or contract, leading to potential damage. Using sleeves helps maintain a consistent environment around the pipes. This can be vital in sensitive projects, such as data centers or laboratories.

Moreover, pipe sleeves can control condensation. When warm, humid air contacts colder pipes, water may form and drip. This not only damages surrounding materials but can also promote mold growth. With sleeves, the risk of condensation is significantly lowered. However, the choice of material for these sleeves is often overlooked. Not every material suits every climate or project type. Without proper consideration, builders may face unexpected failures.

Additionally, improper installation of pipe sleeves can lead to gaps. These gaps may allow temperature fluctuations to undermine the sleeve’s effectiveness. It's important to regularly check the installation. Regular maintenance isn’t just a benefit; it’s a necessity. Over time, wear can compromise the control of temperature and humidity, requiring diligent inspections. By focusing on these details, contractors can prevent costly repairs.

Related Posts

-

Unlocking the Advantages of Pipe Sleeve Solutions for Global Procurement

-

Innovative Pipe Sleeve Solutions Unveiled at the 138th Canton Fair 2025 in China

-

How to Choose the Right Pipe Sleeve for Your Project?

-

How to Use Trenchless Technology for Effective Sewer Repair Solutions

-

Top 10 Effective Techniques for Well Pipe Repair You Should Know

-

Unlocking the Benefits of Sleeve Sewer Line Technology for Efficient Waste Management