2026 Top Trends in No Dig Pipe Repair Solutions?

In recent years, no dig pipe repair solutions have become increasingly popular. These innovative methods offer various benefits to property owners and contractors. They minimize disruption to landscapes and reduce the need for extensive excavation. With urban areas rapidly growing, traditional pipe repair methods are becoming less practical.

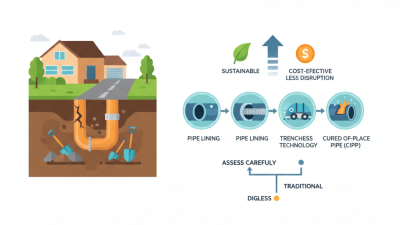

By 2026, we expect to see several trends emerge in the no dig pipe repair industry. These trends will focus on technology advancements, efficiency improvements, and sustainability. For example, more contractors are adopting trenchless technology to streamline their repair processes. Companies are investing in equipment that can detect issues without invasive digging.

While these solutions provide many advantages, they require careful consideration. Some may argue that these methods are still relatively new and can be unpredictable. It's crucial for contractors to weigh the pros and cons of no dig pipe repair methods. Overall, the future of this industry is bright, yet challenges remain.

Emerging Technologies in No Dig Pipe Repair Solutions for 2026

No dig pipe repair solutions are evolving rapidly. In 2026, new technologies will enhance efficiency and reduce costs. The focus is on innovative methods that target trenchless excavations. Techniques are now more precise, which minimizes disruption to the surrounding environment. This trend supports sustainability while maintaining essential infrastructure.

Innovations include robotic systems. These can navigate through existing pipelines, locating and repairing issues with minimal disturbance. Such technology allows for more accurate assessments of pipe conditions. Yet, there are challenges. Operators need extensive training to fully utilize these tools. The integration process can be slow, sometimes hindering immediate benefits.

Another promising development is the use of advanced materials. These materials are designed for longevity and can withstand harsh conditions. However, not every system adapts easily to these new materials. Some existing infrastructure may require upgrades that aren’t feasible in the short term. Adaptability remains a critical factor in the successful adoption of these solutions.

2026 Top Trends in No Dig Pipe Repair Solutions

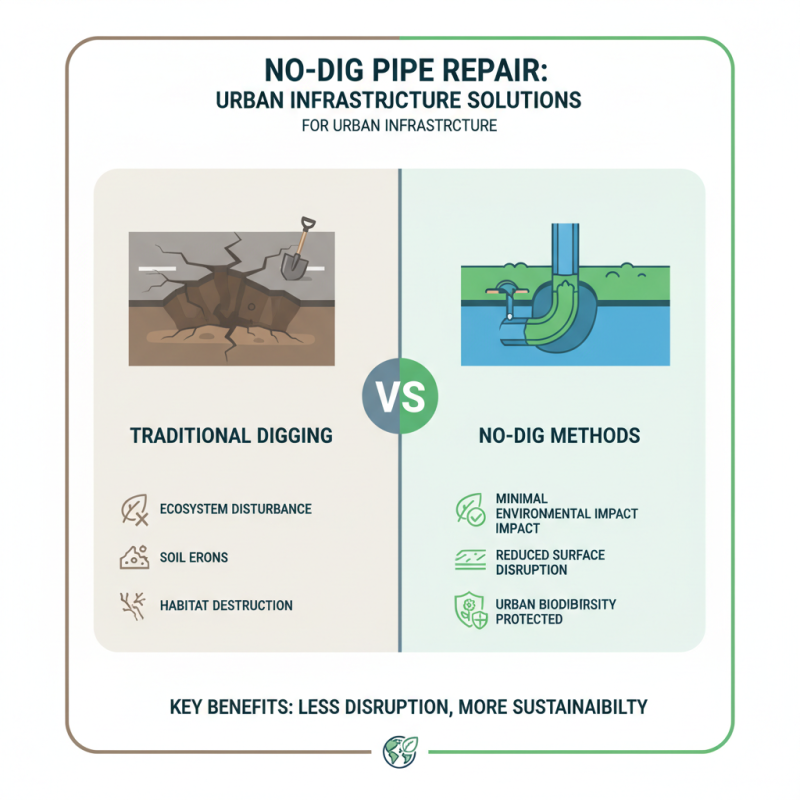

Environmental Impact of No Dig Techniques on Urban Infrastructure

No dig pipe repair techniques have emerged as vital solutions for urban infrastructure. Recent studies indicate that these methods significantly reduce environmental impact. Traditional digging methods often disturb ecosystems, causing soil erosion and habitat destruction. In contrast, no dig solutions minimize surface disruption, leading to fewer negative effects on urban biodiversity.

One key study from the American Society of Civil Engineers noted that reducing surface disruption can decrease carbon emissions by about 30%. This is crucial in densely populated areas. The methods also lower noise pollution, benefiting residents. Cities are evolving, and their infrastructure must change accordingly.

Tips: When considering no dig techniques, assess the specific urban environment. Each area has unique challenges. Engage with local communities to understand their concerns and preferences.

While no dig methods are largely advantageous, they aren't flawless. Challenges include the initial cost and the need for skilled technicians. Moreover, awareness of these techniques is still growing, leading to some misconceptions. Encouraging more research and community discussions can help address these gaps.

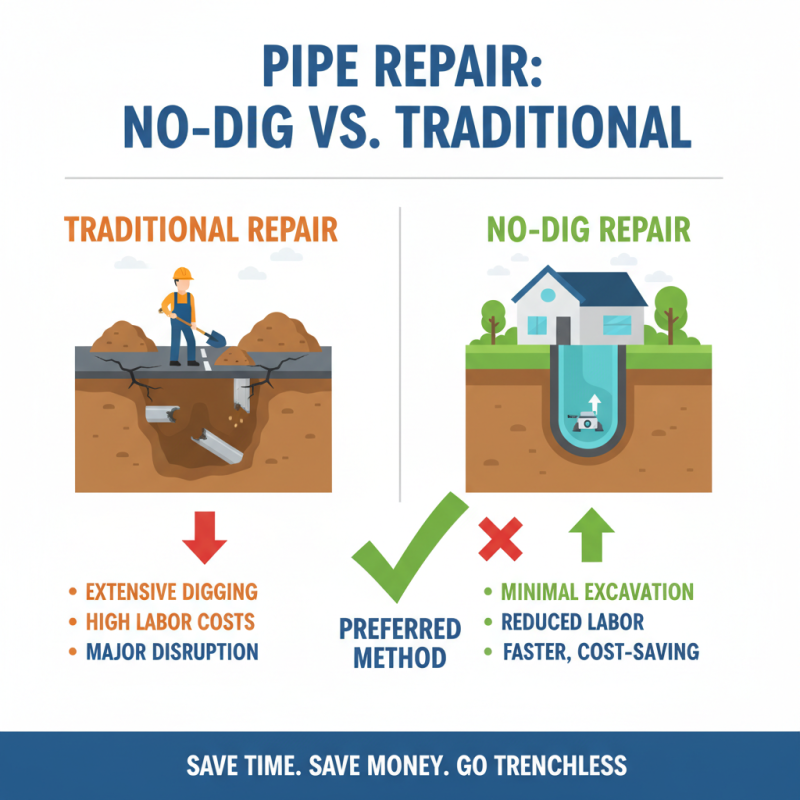

Cost-Effectiveness of No Dig Methods Compared to Traditional Repairs

No dig pipe repair methods are gaining popularity. They offer significant cost savings compared to traditional repair techniques. Traditional methods often involve extensive digging, which can lead to disruption and higher labor costs. In contrast, no dig methods allow for repairs without disturbing the surface. This can save both time and money.

Tips: Plan ahead. Evaluate the site conditions before choosing a no dig solution. Each project is unique, and understanding the specifics can help avoid unexpected costs.

Additionally, no dig technologies can reduce the need for restoration. Traditional repairs often require paving or landscaping work afterward, increasing overall expenses. When using no dig solutions, the site remains mostly intact, leading to fewer restoration costs.

Tips: Consider training for your team. Understanding how to implement no dig techniques properly can enhance efficiency. It can also lead to better project outcomes, reducing the risk of errors.

Trends in Materials Used for No Dig Pipe Repairs in 2026

As we approach 2026, the landscape of no dig pipe repair solutions is evolving. Innovative materials are leading the charge. For instance, advancements in thermoplastic polymers offer enhanced flexibility and durability. These materials can adapt to various soil conditions, reducing the risk of failure. The potential for self-healing capabilities is also a game changer. Imagine pipes that can seal minor leaks on their own!

It's not just about materials; installation techniques are shifting too. Trenchless methods are becoming more refined. This means less disruption to the environment and surface structures. The use of smart sensors integrated into pipes is on the rise. These sensors monitor conditions in real time, providing crucial data. However, reliance on technology raises concerns. Are we overlooking basic repair techniques in favor of high-tech solutions?

While these trends are promising, they bring challenges. Cost-effectiveness must be considered. Implementing new materials and technologies can be expensive. There is a learning curve associated with training personnel. Moreover, not all municipalities will adapt at the same pace. Balancing innovation with practicality is essential as we look to the future.

2026 Top Trends in No Dig Pipe Repair Solutions

| Trend | Material Used | Application | Benefits |

|---|---|---|---|

| Increased Use of Composite Materials | Fiber-Reinforced Polymers (FRP) | Water Main Repairs | High strength-to-weight ratio, corrosion resistance |

| Emergence of Self-Healing Materials | Microcapsule-Embedded Polymers | Pipeline Rehabilitation | Reduces maintenance needs and extends lifespan |

| Advancements in Robotic Technology | Flexible Robotics with RFID | Inspection and Repair | Improved efficiency, safety in hazardous environments |

| Sustainable and Green Materials | Recycled Plastics | Utility Repairs | Environmental benefits, reduced carbon footprint |

| Integration of IoT in Pipe Repair | Smart Surface Coatings | Leak Detection Systems | Real-time monitoring, proactive maintenance |

Future Challenges and Innovations in No Dig Pipe Repair Solutions

The landscape of no dig pipe repair solutions is rapidly evolving. As urban infrastructure ages, traditional methods struggle to keep pace. Adopting innovative techniques is essential for modernizing how we approach underground repairs. This trend is driven by growing urbanization and the increasing need for maintenance without disruption.

Emerging technologies are reshaping the field. Advances in robotic technology and inspection tools are enabling more precise repairs. However, challenges remain. Many companies grapple with the high costs associated with new technologies. Training workers on these systems can be a slow process. Not every team adapts easily, leading to potential setbacks in implementation.

Environmental concerns are pushing for greener solutions. Sustainable materials are being explored, yet their viability is still in question. Do they match the durability of existing materials? Ongoing research aims to bridge this gap. Embracing these innovations can yield great benefits, but skepticism still lingers in the industry. The journey toward efficient no dig methods is complex and requires ongoing evaluation and adaptation.

Related Posts

-

Why No Dig Pipe Repair is the Future of Sustainable Plumbing Solutions

-

Complete Guide to Efficient CIPP Pipe Repair Techniques for Modern Infrastructure

-

How to Successfully Perform No Dig Pipe Repair for Lasting Results

-

2026 Top Digless Pipe Repair Techniques for Efficient Plumbing Solutions

-

Ultimate Guide to Digless Pipe Repair Tips for Homeowners?

-

Unlocking the Advantages of No Dig Sewer Repair for Modern Infrastructure