2026 Top Sewer Pipe Sleeve Innovations and Solutions?

In the rapidly evolving industry of sewer pipe sleeves, innovation is key. As we approach 2026, new developments promise to enhance the durability and efficiency of sewer systems. Industry expert, Dr. Emma Larson, notes, “The future of sewer pipe sleeves hinges on sustainable materials and smart technology.” Her insight emphasizes the need for the sector to address both environmental and functional challenges.

Sewer pipe sleeves have gained attention for their ability to protect aging pipes from corrosion and leakage. However, innovation does not come without challenges. The integration of new materials can lead to compatibility issues. Stakeholders must carefully consider these factors to ensure successful implementations.

Moreover, while technology improves efficiency, it often raises questions about cost. Innovations can be expensive, risking the investment return for smaller municipalities. The balance between cutting-edge solutions and practical affordability is still a work in progress. Addressing these complexities will be vital as we explore the future of sewer pipe sleeves.

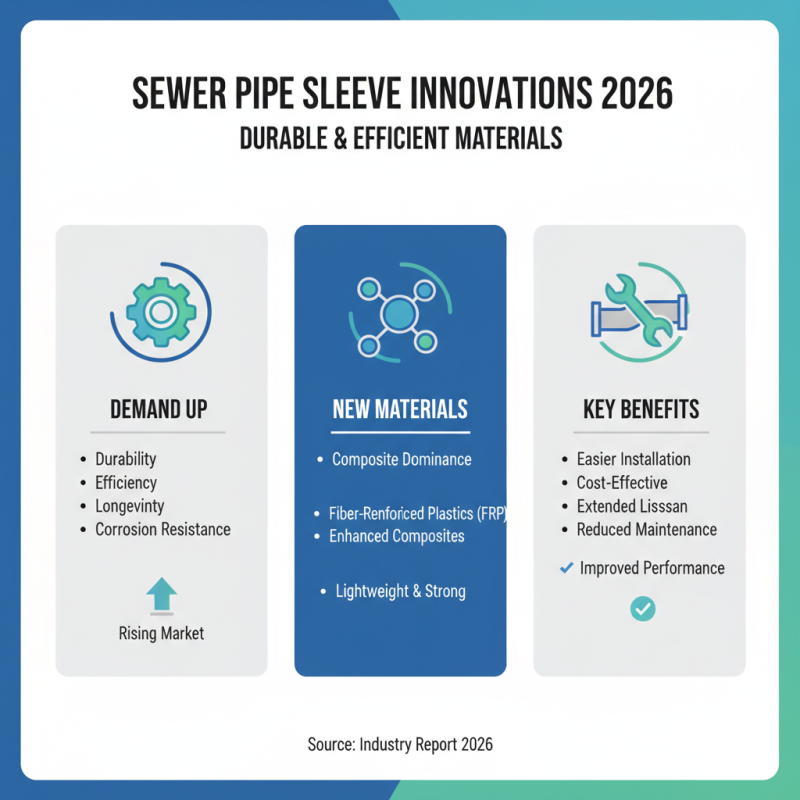

Innovative Materials in Sewer Pipe Sleeve Design for 2026

Innovative materials play a critical role in sewer pipe sleeve design for 2026. The demand for durable and efficient solutions is rising. New composites will likely dominate the market. These materials offer enhanced resistance to corrosion and improve longevity. Innovations such as fiber-reinforced plastics are gaining attention. They combine strength with lightweight properties, making installation easier and cost-effective.

Tips: Consider the environmental impact when choosing materials. Recyclable options are becoming more popular. They can reduce waste and promote sustainability.

The technology used in these sleeves is evolving. Smart sensors could be integrated to monitor conditions inside the pipes. This would provide real-time data, preventing leaks and blockages. However, the adoption of such technologies has challenges. Cost and complexity might deter some projects.

Many engineers are experimenting with bio-based materials. These could revolutionize the industry by reducing reliance on traditional plastics. In contrast, some designs may require extensive testing to ensure reliability. Balancing innovation with proven practices remains a priority.

Advancements in Sewer Pipeline Rehabilitation Techniques

Advancements in sewer pipeline rehabilitation are crucial for urban infrastructure. Traditional methods often involve extensive excavation, which is disruptive. Newer approaches focus on minimizing surface impact while restoring pipeline functionality. Technologies like trenchless rehabilitation reduce the need for open-cut excavation. They are efficient and help preserve public space.

Innovations include the use of pipe-sleeving technologies. This technique involves inserting a liner into the existing pipe. It forms a new, structural pipe within the old one. This method is both effective and cost-efficient. Yet, it isn't without challenges. Proper evaluation of existing conditions is critical. Without accurate assessments, the rehabilitation may fail.

Environmental concerns are also paramount. While new materials show promise, their long-term impact is still under review. Balancing innovation with sustainability is not straightforward. Municipalities face pressure to modernize while ensuring eco-friendly practices. The road ahead will demand collaboration and constant refinement of techniques. There is much to learn from both successes and setbacks in this evolving field.

Eco-Friendly Solutions for Sewer Pipe Sleeve Applications

The need for eco-friendly solutions in sewer pipe sleeve applications is urgent. Innovations in materials like biodegradable plastics are gaining traction. These materials can reduce environmental impact significantly. They degrade over time, lessening the burden on landfills. Their use can lead to cleaner water systems.

Choosing the right material is crucial. Some options may not perform well in different soil conditions. Not all green alternatives are suitable for every application. Conducting thorough assessments is essential. This can identify potential risks and benefits.

Here are some tips. Always test new materials in controlled settings. Monitor their performance closely over time. Consider the long-term environmental impacts, not just initial cost. Sustainability should drive your decision-making. By staying informed, you can make better choices. Eco-friendly solutions can reshape sewer management for the better.

2026 Top Sewer Pipe Sleeve Innovations and Solutions

| Innovation Type | Material Used | Environmental Impact | Longevity (Years) | Cost (per unit) |

|---|---|---|---|---|

| Self-Healing Sleeves | Bio-based Polymers | Low carbon footprint | 50 | $45 |

| Recycled PVC Sleeves | Recycled PVC | Recyclable material | 30 | $30 |

| Composite Sleeves | Fiberglass and Epoxy | Durable and long-lasting | 75 | $60 |

| Smart Monitoring Sleeves | Smart Sensors and Polymer | Environmental monitoring | 20 | $100 |

| Biodegradable Sleeves | Starch-based Polymers | Fully biodegradable | 10 | $25 |

Cutting-Edge Technologies in Sewer Inspection and Maintenance

Sewer inspection and maintenance technology is evolving rapidly. New innovations focus on efficiency and safety. For example, recent studies indicate that robotic inspection tools can reduce labor costs by up to 30%. These devices navigate through pipes, capturing high-resolution images and data. This provides valuable insights into pipe conditions, showing cracks and blockages effectively.

In addition to robotics, trenchless technology is gaining popularity. A report estimated that trenchless methods can save about 50% in restoration costs. By minimizing surface disruption, communities can avoid costly repairs. However, some technologists still struggle with integration. Not all regions have the right equipment or trained personnel.

Data analytics also plays a key role. Predictive maintenance can alert teams about potential failures. However, the accuracy of data collection remains a concern. An estimated 25% of datasets can contain errors. These inaccuracies could mislead repair schedules and priorities. Understanding this complexity is crucial for future improvements in sewer maintenance.

Future Trends in Sewer Pipe Sleeve Innovations and Industry Standards

As we look towards 2026, sewer pipe sleeve innovations will reshape the industry. Many new materials are being tested. Flexible and durable sleeves are becoming the standard. They promise longevity and resistance to harsh conditions. These innovations aim to reduce the frequency of repairs. However, challenges remain in ensuring compatibility with existing infrastructures.

Industry standards are evolving alongside these developments. There is a growing emphasis on sustainability. Eco-friendly materials are emerging as viable options. Research into reducing environmental impact is critical. Yet, some designs still require improvements. Adaptability to different soil types is one issue. Some materials struggle under extreme conditions. Ongoing testing and feedback loops are essential for progress.

Collaboration among engineers, manufacturers, and regulators is vital. Continuous dialogue can help identify standards that meet current and future needs. There's a need for more rigorous testing protocols too. Innovations should not just aim for functionality, but enhance safety. Addressing these aspects will ensure that the future of sewer pipe sleeves is bright and effective.

Related Posts

-

What is a Sewer Pipe Sleeve and How Does It Work

-

Innovative Sewer Pipe Sleeve Solutions Showcase at the 138th China Import and Export Fair 2025

-

How to Identify Signs Your Sewer Line Needs Immediate Attention

-

Unlocking the Benefits of Sleeve Sewer Line Technology for Efficient Waste Management

-

2026 Best Tips for Well Repair Techniques and Solutions?

-

Creative Applications of Sewer Pipe Sleeve Repair Techniques