2025 Top Tips for Effective Pump Repair: Common Issues and Solutions

In many industrial and commercial settings, the reliability of pumps is crucial for maintaining efficient operations. As pivotal components in various processes, these machines often face a range of challenges that necessitate effective pump repair strategies. Understanding common issues that can arise, such as leaks, mechanical failures, or performance inefficiencies, is vital for mitigating downtime and reducing costs associated with unexpected repairs.

In this article, we will delve into the top tips for effective pump repair, examining proven solutions to frequently encountered problems. By exploring practical strategies and insights, we aim to equip technicians and maintenance teams with the knowledge required to enhance the longevity and performance of their pumping systems. Whether you're dealing with minor wear and tear or significant operational challenges, the following guidance will help streamline your pump repair efforts, ensuring optimal performance and reliability.

Understanding Common Pump Issues and Their Symptoms

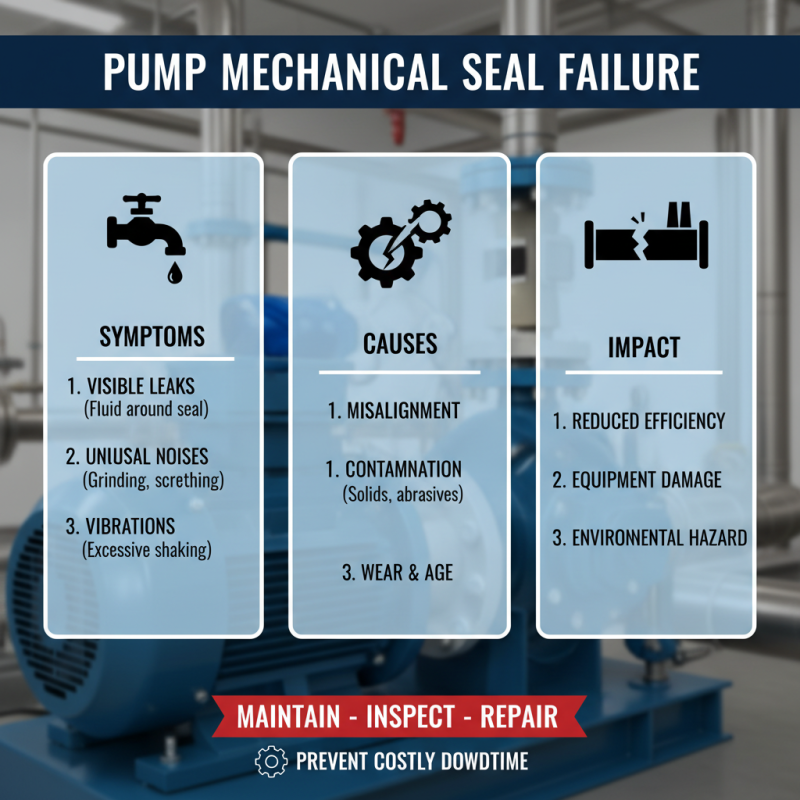

Pumps are critical components in various industrial applications, and understanding their common issues and symptoms is essential for effective maintenance and repair. One prevalent problem is mechanical seal failure, which can lead to leaks and reduced efficiency. Symptoms often include visible fluid escaping around the seal area, unusual noises during operation, or vibrations that are not typical for the equipment. Addressing seal integrity promptly can prevent more extensive damage to the pump and its surroundings.

Another common issue is cavitation, which occurs when vapor bubbles form in the pump and collapse violently, causing damage to impellers and other components. Symptoms of cavitation include a noticeable decrease in performance, increased noise levels, and a distinct change in the sound of the pump operation. To mitigate cavitation, it's essential to ensure that the pump is operating within its recommended flow ranges and to check for any obstructions in the intake.

Lastly, bearing wear can significantly impact pump performance. Symptoms indicative of bearing issues include excessive heat, unusual grinding noises, and misalignment. Regular inspection and lubrication of bearings can prolong their lifespan and maintain smooth operation. Identifying these common symptoms early can enhance pump reliability and reduce unexpected downtime in operations.

Step-by-Step Guide to Diagnosing Pump Problems

Diagnosing pump problems effectively is crucial for maintaining operational efficiency and minimizing downtime. According to the Hydraulic Institute, approximately 75% of pump failures can be traced back to issues in installation, maintenance, or operation. Identifying the root cause of a pump's malfunction often begins with a systematic step-by-step approach. Start by checking for common signs of distress, such as unusual noises, vibrations, or leaks. These symptoms can indicate issues ranging from cavitation to misalignment, allowing technicians to narrow down the potential problems.

Once initial signs are assessed, operators ought to conduct a thorough visual inspection and monitor operational parameters. Data from the American Society of Mechanical Engineers highlight that nearly 40% of pump inefficiencies arise from misaligned shafts and improper bearings. Measuring flow rates, pressure levels, and temperature can help further pinpoint problems. Utilizing advanced diagnostic tools, such as vibration analysis and infrared thermography, can reveal underlying issues that aren’t immediately visible. By adhering to these diagnostic steps, maintenance teams can address pump issues proactively, leading to more effective repairs and enhanced system reliability.

2025 Top Tips for Effective Pump Repair: Common Issues and Solutions

| Common Issues | Symptoms | Diagnosing Steps | Solutions |

|---|---|---|---|

| Leakage | Water pooling around the pump | Check for loose fittings, inspect seals | Tighten fittings or replace seals |

| Noisy Operation | Unusual sounds during operation | Listen for bearing noise, check impeller | Lubricate bearings or replace impeller |

| Low Pressure | Inadequate water flow | Inspect inlet for blockages, check pressure gauge | Clear blockages or adjust settings |

| Overheating | Pump shuts down frequently | Check for adequate airflow, assess coolant level | Improve ventilation or replenish coolant |

| Cavitation | Inconsistent flow rates | Monitor flow rate, inspect for air bubbles | Adjust suction pipe length or reduce fluid temperature |

Effective Techniques for Pump Repair and Maintenance

When it comes to pump repair and maintenance, a proactive approach can save both time and resources. Regular inspection of pumps is essential; this includes checking for leaks, unusual noises, and vibrations that could indicate wear or damage. Identifying these issues early can prevent costly breakdowns and ensure the longevity of the equipment. Maintaining proper lubrication and monitoring fluid levels are also critical practices. This not only helps in smooth operation but also minimizes the risk of overheating and mechanical failure.

In addition to routine checks, implementing a structured maintenance schedule tailored to the specific operational environment of the pump can significantly enhance reliability. Techniques such as vibration analysis and thermal imaging can be utilized to gather real-time data on pump performance. These advanced methods allow technicians to predict potential failures before they occur, enabling timely interventions. Moreover, creating a clear documentation system for maintenance activities can aid in identifying patterns and recurring problems, streamlining future repair efforts and ensuring effective solutions are applied consistently.

Preventative Measures to Extend Pump Longevity

Preventative measures play a crucial role in extending the longevity of pumps and maintaining their operational efficiency. According to a report by the Hydraulic Institute, nearly 30% of pump failures can be attributed to inadequate maintenance practices. Regular inspections, coupled with predictive maintenance techniques, can significantly mitigate potential breakdowns. Implementing a scheduled maintenance program that includes routine checks on components such as seals, bearings, and impellers can help identify wear and tear before they escalate into major issues.

Furthermore, proper operational procedures cannot be underestimated. The American Society of Mechanical Engineers (ASME) highlights the importance of avoiding cavitation, overheating, and overloading—factors that contribute to premature pump failures. Training operators to adhere to optimal operating conditions and regularly monitoring pump performance statistics can lead to a more reliable system. Incorporating advanced monitoring technologies, such as vibration analysis and thermal imaging, allows for early detection of anomalies, which is essential for proactive maintenance and extends pump lifespan significantly.

Tools and Resources for Successful Pump Repairs

When it comes to effective pump repairs, having the right tools and resources can make all the difference. According to a recent industry report by the Hydraulic Institute, over 70% of pump failures are attributed to inadequate maintenance and lack of proper diagnostic tools. This emphasizes the importance of being equipped with both the knowledge and tools necessary for successful repairs.

One essential tool for pump repair is a reliable multimeter, which helps detect electrical issues that could be affecting pump performance. For mechanical problems, consider investing in vibration analysis equipment, as studies show that early detection of vibration-related issues can prevent equipment failure and extend the lifespan of pumps by up to 25%. To further enhance your repair capabilities, ensure that you have access to comprehensive repair manuals and online resources that focus on common pump models and their specific maintenance techniques.

Tip 1: Regularly schedule maintenance checks to identify potential issues before they lead to costly repairs. A proactive approach can save time and resources in the long run.

Tip 2: Utilize online forums and industry publications to stay updated on the latest repair techniques and technologies. Networking with other professionals can also provide invaluable insights and troubleshooting advice.

Incorporating these tools and resources into your pump repair strategy can significantly improve operational efficiency and reduce downtime. Whether you are a seasoned technician or a novice, staying informed and equipped is key to successful pump maintenance.

Related Posts

-

Comprehensive Pump Repair Checklist for Efficient Plant Operations and Reduced Downtime

-

How to Identify Common Symptoms of Pump Issues Before Calling for Repair

-

How to Identify Signs Your Sewer Line Needs Immediate Attention

-

How to Use Trenchless Technology for Effective Sewer Repair Solutions

-

How to Effectively Use Sewer Pipe Sleeve Repair for Long-Lasting Solutions

-

7 Essential Tips for Effective Home Sewer Line Repair You Can't Ignore